PRODUCT DATA SHEET

Edition 01/2020

Version 001

30000260

TABLE TOP EPOXY

PRODUCT DESCRIPTION

SIMIRON Table Top Epoxy is a professional-grade, high-performance, ultra-clear, self-leveling, high-gloss, 100% solids epoxy resin coating. SIMIRON Table Top Epoxy is great

for craft and furniture projects requiring a strong protective finish. It is great for river tables, live edge tables and countertops, bar tops, wood finishes, artwork and other creative

applications. For a truly custom appearance, SIMIRON Table Top Epoxy can be mixed with pigment and mica powders, glitter, glow-in-the-dark pigments, alcohol inks, resin dyes

and tints. SIMIRON Table Top Epoxy can be poured up to 1/8” thick with excellent air release, making it simple to achieve flawless results. SIMIRON Table Top Epoxy features an

easy-to-use 1:1 mix ratio.

MIXING

For best results product should be used at 75-85°F. Combine the Part A Resin and Part B Hardener in a clean container, at the proper 1 to 1 mix ratio by volume. It is very

important the proper mix ratio is followed. Mixing a different ratio could cause product to not cure properly and lead to tacky areas or product failure. Mix product using a clean

mixer or stick for 3 – 5 minutes. Be sure to mix gently so that excessive air isn’t incorporated during mixing. Mixing too aggressively can lead to a cloudy appearance as well as

surface imperfections. Gently transfer mixed material into another clean container and mix for an additional minute.

Product should be used immediately after mixing.

Do not use product that has begun to cure.

Do not mix product longer than eight minutes.

Over mixing will prematurely initiate the curing process.

RECOMMENDED USES

• Bars

• Table Tops

• Furniture

• Artwork

• Display tops

• Craft projects

THEORETICAL COVERAGE

One gallon will cover approximately 12 square feet at 1/8” thickness.

SURFACE PREPARATION

Surface should be clean and dry. SIMIRON Table Top Epoxy and materials to be

coated should be at the same temperature. If using wood, it should be clean and

dry and free of excessive internal moisture. Properly cover or mask surrounding

areas to protect from spilled or dripped epoxy.

FEATURES & BENEFITS

• Self-Leveling

• Crystal Clear

• Excellent Air Release

• Easy-To-Use

• 100% Solids

• Safe For Incidental Food Contact

• No VOC’s

• No Odor

• Scratch and Impact Resistant

• UV Resistant

• Extremely Durable

• High Gloss

• Blush Resistant

• Water Resistant

SIMIRON | TABLE TOP EPOXY PAGE 1 OF 3

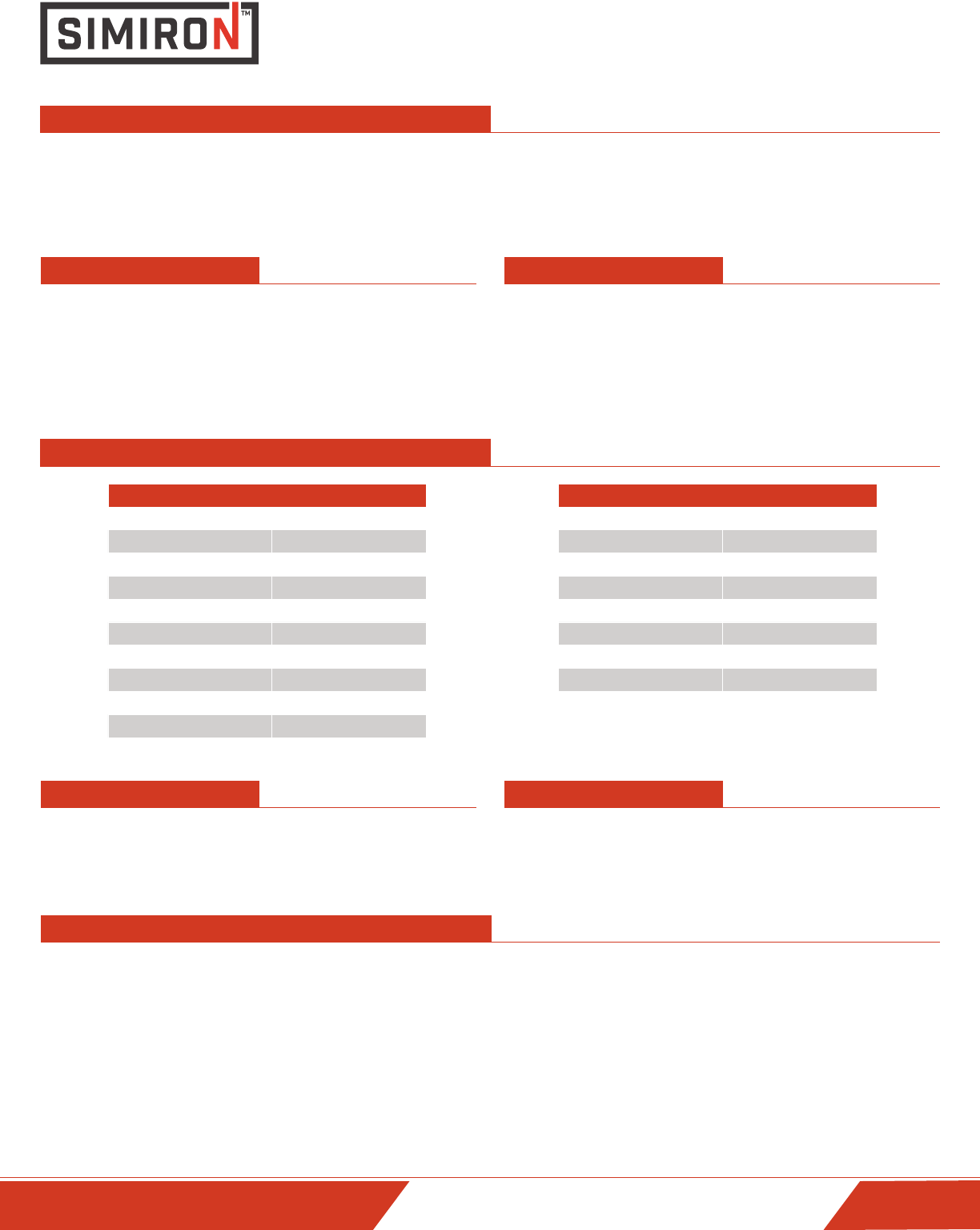

TECHNICAL DATA

PHYSICAL DATA

Finish High Gloss

Resin Type Epoxy

Max Pour Depth 1/8”

Hardness Shore D 85

Cure Time 24 hours

Mix Ratio (by volume) 1:1

Mix Ratio (by weight) 100A:83B

Pot Life 45 min

Mixed Viscosity 3,500 cPs

Volume Solids 100%

PHYSICAL DATA

Weight Solids 100%

VOC 0 g/L

UV Resistant Excellent

Blush Resistant Excellent

Air Release Excellent

Scratch Resistance Excellent

Self-Leveling Excellent

Impact Resistant Excellent

Clarity Excellent

PRODUCT DATA SHEET

Edition 01/2020

Version 001

30000260

TABLE TOP EPOXY

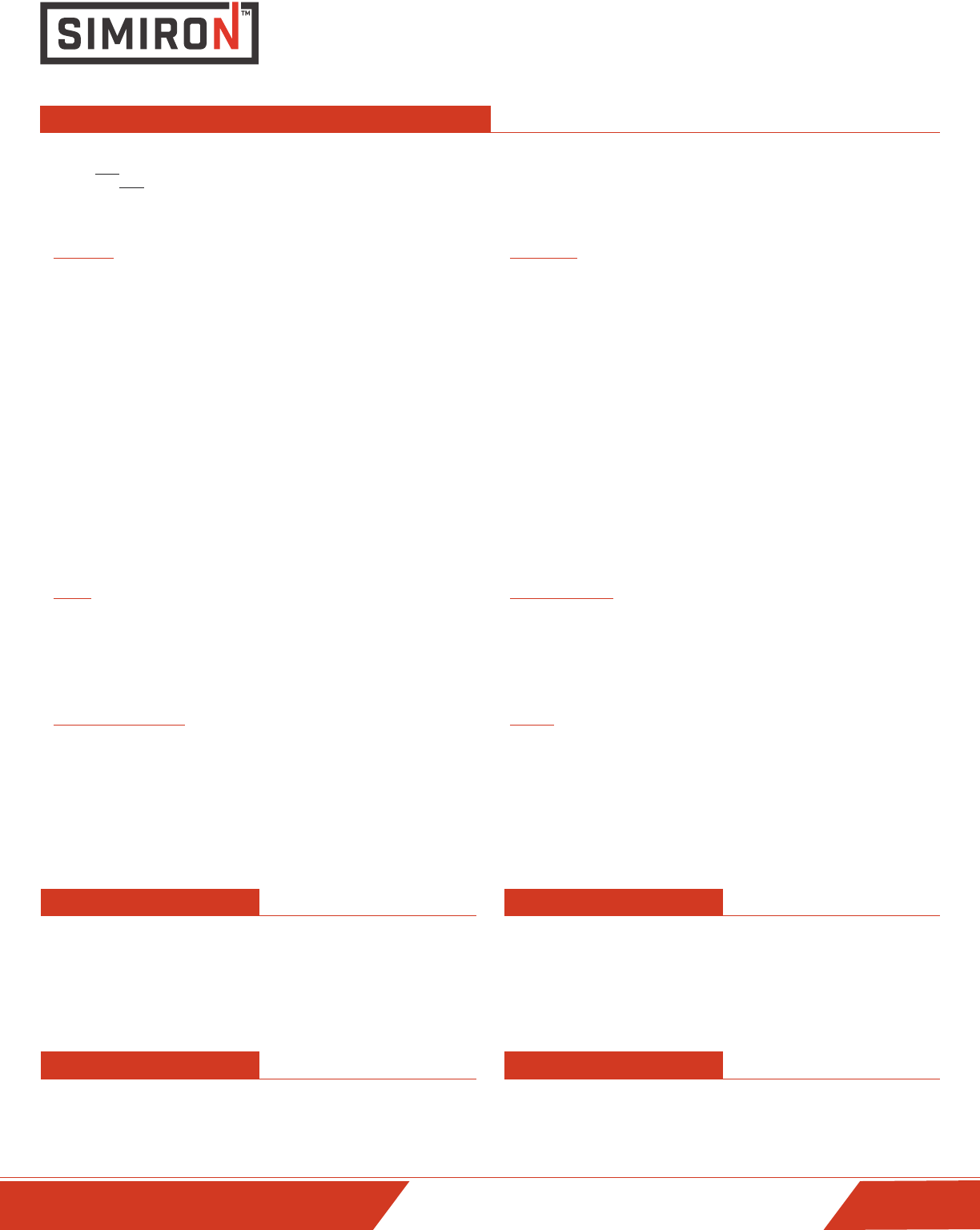

PACKAGING

Size/Finish Item Number

Table Top Epoxy — 1 Gal Kit 40005641

CLEAN UP

Wash hands with soap and warm water. Clean tools using a solvent such as

acetone, nail polish remover or denatured alcohol. Follow solvent manufactures

SDS while using.

SHELF LIFE AND STORAGE

Shelf life is 12 months when stored in factory-sealed containers indoors at 60°F to

80°F (15°C to 27°C) for Base and Activator. Keep containers tightly sealed.

DO NOT FREEZE. Keep away from sparks or flames.

Do not place containers against an exterior wall or on the floor.

If resin component thickens or crystallizes, it may be reconditioned by placing the

container in a bath of warm water (approximately 150°F) and slowly stirring until

product liquefies.

LIMITATIONS

Do not use in low-temps

Do not use over oil-based products.

Do not apply over 1/8” thick.

Do not use in high humidity conditions.

Do not use material that has crystallized.

SIMIRON | TABLE TOP EPOXY PAGE 2 OF 3

INSTALLATION

Simiron recommends that all application instructions be followed to ensure satisfactory results.

Product must be between 75 – 80°F before use. Product container may be placed in warm water until proper temperature is achieved.

Environment must be between 75 – 80°F during application and curing process. Environment should also be free of dust and other airborne contaminates.

Before starting a project, care should be taken to ensure that enough SIMIRON Table Top Epoxy is available to complete the project. A shortage of material may result in

undesired results.

SEAL COAT:

It is best to determine if your surface needs a seal coat before starting your project.

Seal coats are important because porous or rough surfaces may lead to excessive air

bubbles. Seal coating the surface will help prevent air bubbles from attaching to the

surface.

SIMIRON Table Top Epoxy may be used as the seal coat. Porous or unsealed wood such

as tabletops, bars, hardwood, barnwood, knotty wood or other types of wood should

be sealed before applying flood coat. Well-seasoned or dry wood such as barnwood or

kiln dried wood may require multiple seal coats. When pouring over aluminum, copper,

stainless steel, plastic laminate (like Formica®), or other non-porous surfaces a seal

coat is not needed. Be sure that these surfaces are clean and free of contaminates such

as oil or grease.

Allow any stains, varnishes or other coatings to completely dry before applying seal coat

overtop. Do not apply over oil-based finishes.

Delicate objects such as pictures may be damaged by epoxy resin and should be sealed

with an acrylic or polyurethane coating before embedding with epoxy resin.

If a seal coat is needed only mix a small batch of material, as the material will cover a

much larger area. Use a brush to spread a thin coat over the surface. Allow seal coat to

dry a minimum of 4 - 6 hours before applying the flood coat.

FLOOD COAT:

To prevent pooling and an uneven coat of material, ensure that the surface to be

coated is as level as possible. Flood coat should be applied at 1/8” thick or less.

If thicknesses greater than 1/8” are desired, then multiple coats will need to be

applied. Allow flood coat to cure between 4 – 10 hours before applying a second flood

coat.

Apply flood coat by starting on one end and pour the resin the entire length of the

surface. Evenly pour the mixed resin across the surface using a zig-zag pattern.

After all material is poured, do not try to scrape any additional material out of the

container. Material will begin to flow and self-level. If there are areas where thicker

amounts of material may have been poured, you may move it around using a notched

plastic trowel, squeegee or foam brush.

EDGES:

Flood coats may be allowed to run over the edges. Vertical edges will not be as thick as

horizontal surfaces so be sure to use a brush to ensure the coating is evenly applied on

the edge. Drips will form underneath the edge during the leveling and curing process.

Using a flat scraper, excess drips can be removed prior to final curing. Drips that

harden can be removed by sanding once the coating is fully cured.

ADDITIONAL COATS:

Allow flood coat to cure between 4 – 10 hours before applying a second flood coat.

If allowed to cure for longer than 10 hours, it is recommended to lightly sand the

surface using a 220 – 300 grit sandpaper to ensure proper adhesion between layers.

Wipe sanded surface clean with a tack-cloth or solvent such as acetone or denatured

alcohol so that no debris from sanding is entrapped. Follow flood coat application

directions again for each additional coat applied.

REMOVING AIR BUBBLES:

Allow the flood coat to level for 15 minutes after application before starting the air

bubble removal. Air bubbles are created from product mixing, application and surface

tension so it’s perfectly normal to see these, but it is important to remove them. The

best tools for removing air bubbles are a handheld propane torch or heat gun. Hold the

torch or heat gun approximately 6 – 10 inches away from the coating and quickly move

around the surface. You will see the air bubbles pop immediately. Continue doing this

method every 10 – 15 minutes until all bubbles are removed. This may take up to an

hour to remove all entrapped bubbles. Prevent the torch from getting too close to

the coating and do not hold the torch in one area for too long, as scorching can occur.

CURING:

After application of the final coat, the coating should be allowed to properly cure in

a controlled, clean, and dust-free environment free of contaminates at 75 – 80°F for

12 – 14 hours. Allow coating to cure a minimum of 72 hours before returning into full

service. Waiting 72 hours will allow the coating to achieve sufficient hardness and

scratch resistance.

Tack Free: 12 – 14 hours

Full Cure: 72 hours

PRODUCT DATA SHEET

Edition 01/2020

Version 001

30000260

TABLE TOP EPOXY

Corporate Office

SIMIRON

32700 Industrial Drive

Madison Heights, MI 48071

(248) 686-3600 / (866) 515-8775

Disclaimer:

All information provided by Simiron, Inc. concerning Simiron products, including but not limited to, any recommendations and advice relating to the application and use of Simiron products, is given

in good faith based on Simiron’s current experience and knowledge of its products when properly stored, handled and applied under normal conditions in accordance with Simiron’s instructions. In practice,

the differences in materials, substrates, storage and handling conditions, actual site conditions and other factors outside of Simiron’s control are such that Simiron assumes no liability for the provision of such

information, advice, recommendations or instructions related to its products. The use of Simiron product(s) must test the product(s) for suitability for the intended application and purpose before proceeding

with the full application of the product(s).

Simiron reserves the right to change the properties of its products without notice. All sales of Simiron product(s) are subject to its current terms and conditions of sale which are available by calling

(866) 515-8775.

QUESTIONS?

866.515.8775

LIMITED WARRANTY

SIMIRON warrants this product to be free from defect in the material that affects its

performance for a period of 10 years (from date of purchase). SIMIRON will replace

at no charge the quantity of the Coating that SIMIRON determines has failed to

perform, as the sole and exclusive remedy for any breach of this warranty and/

or any other defect or failure of the coating. Proof of purchase is required. Cost of

labor for application of any product specifically is excluded.

TECHNICAL ASSISTANCE

Information is available by calling SIMIRON:

Toll Free: 1.866.515.8775 / Telephone: +1.248.686.3600

TECHNICAL & SAFETY LITERATURE

To acquire additional information or technical and safety literature, please visit:

www.simiron.com

SIMIRON | TABLE TOP EPOXY PAGE 3 OF 3