“DRAFT”

U.S. Department

of Transportation

Federal Aviation

Administration

Advisory

Circular

Subject: Minimum Equipment Requirements

for General Aviation Operations

Under 14 CFR Part 91, § 91.213

Date: DRAFT AC No: AC 91-67A

Initiated by: AFS-800 Change:

This advisory circular (AC) describes acceptable methods for the operation of aircraft with

certain inoperative instruments and equipment items, which are not essential for safe operations

under Title 14 of the Code of Federal Regulations (14 CFR) part 91, 133, or 137 (including

part 91 operations conducted by parts 141 and 142 certificate holders (CH)).

The contents of this document do not have the force and effect of law and are not meant to bind

the public in any way, and the document is intended only to provide information to the public

regarding existing requirements under the law or agency policies.

This AC describes an acceptable means, but not the only means, to operate an aircraft with

certain inoperative instruments and equipment items that are not essential. While using the

means described in this AC is not mandatory, an operator that voluntarily elects to use the means

described in this AC must follow, in all respects, the terms, conditions, and processes provided in

the AC.

Lawrence Fields

Acting Executive Director, Flight Standards Service

DATE “DRAFT” AC 91-67A

ii

CONTENTS

Paragraph Page

Chapter 1. Introduction ................................................................................................................ 1-1

1.1 Purpose of This Advisory Circular (AC) ...................................................................... 1-1

1.2 Audience ....................................................................................................................... 1-1

1.3 Where You Can Find This AC...................................................................................... 1-1

1.4 What This AC Cancels.................................................................................................. 1-1

1.5 Related 14 CFR Sections .............................................................................................. 1-2

1.6 Related Documents (current editions) .......................................................................... 1-2

1.7 Background ................................................................................................................... 1-2

1.8 Definitions and Terminology ........................................................................................ 1-3

1.9 AC Feedback Form ....................................................................................................... 1-8

Chapter 2. Master Minimum Equipment List (MMEL) .............................................................. 2-1

2.1 General ......................................................................................................................... 2-1

2.2 ATA/JASC Coded System Section Components ......................................................... 2-1

2.3 Obtaining a Current MMEL.......................................................................................... 2-3

2.4 Aircraft for Which No MMEL Has Been Developed ................................................... 2-3

2.5 MMEL PLs ................................................................................................................... 2-3

2.6 MMEL PL Global Change (GC) Designation .............................................................. 2-4

Chapter 3. Minimum Equipment List (MEL) .............................................................................. 3-1

3.1 General ......................................................................................................................... 3-1

3.2 Three Methods for Operating an Aircraft with Inoperative Equipment ....................... 3-2

3.3 MEL LOA ..................................................................................................................... 3-2

3.4 Aircraft Operated Under Multiple 14 CFR Parts .......................................................... 3-3

3.5 Fleet MEL ..................................................................................................................... 3-3

Chapter 4. Conducting Operations Without an MEL .................................................................. 4-1

4.1 Operating Without an MEL .......................................................................................... 4-1

4.2 Removal, Deactivation, and Placarding ........................................................................ 4-1

4.3 Continued Operation with Inoperative Items ................................................................ 4-2

4.4 Safety Risk Analysis of Proposed Operation with Inoperative Equipment Items ........ 4-3

DATE “DRAFT” AC 91-67A

iii

Chapter 5. Conducting Operations with an MEL ........................................................................ 5-1

5.1 Operating with an MEL ................................................................................................ 5-1

5.2 Documentation of Deferred Items ................................................................................ 5-2

5.3 Placarding ..................................................................................................................... 5-2

5.4 Performing (M) and (O) Procedures ............................................................................. 5-2

5.5 Repair of Deferred Instruments or Equipment Items .................................................... 5-3

Chapter 6. Application for MEL Letter of Authorization (LOA) ................................................ 6-1

6.1 Application for an MEL Approval Issued Under LOA D095 ...................................... 6-1

6.2 Application for an MEL Approval Issued Under LOA D195 ...................................... 6-1

6.3 Request for Approval of an MEL That Does Not Conform to This AC....................... 6-1

6.4 Oversight ....................................................................................................................... 6-1

Chapter 7. Content of a Procedures Document ............................................................................ 7-1

7.1 MEL Approval Under LOA D095 ................................................................................ 7-1

7.2 Procedures Document Content ..................................................................................... 7-1

7.3 Procedures Document Required Sections ..................................................................... 7-1

7.4 Procedures Document Optional Sections...................................................................... 7-3

7.5 Example “As Required by 14 CFR” and (M) and (O) Procedures ............................... 7-3

Chapter 8. Content of an Operator-Developed MEL ................................................................... 8-1

8.1 MEL Approval Under LOA D195 ................................................................................ 8-1

8.2 MEL Content ................................................................................................................ 8-1

8.3 MEL Required Sections ................................................................................................ 8-1

8.4 MEL Optional Sections................................................................................................. 8-2

8.5 ATA/JASC Coded System Sections ............................................................................. 8-2

8.6 Example Proviso, “As Required by 14 CFR,” and (M) and (O) Procedures ................ 8-7

Chapter 9. MEL Revisions ........................................................................................................... 9-1

9.1 General ......................................................................................................................... 9-1

9.2 FAA-Initiated MEL Revisions ...................................................................................... 9-1

9.3 Operator-Initiated MEL Revisions ............................................................................... 9-4

9.4 Vertical Bar (Change Bar) ............................................................................................ 9-4

Chapter 10. MEL Relief for Items Installed After Type Certification ....................................... 10-1

10.1 General ...................................................................................................................... 10-1

DATE “DRAFT” AC 91-67A

iv

10.2 Operator NEF Items or Administrative Control Items (ACI) ................................... 10-1

10.3 MMEL Items and MEL Items ................................................................................... 10-1

10.4 MMEL PL-109 .......................................................................................................... 10-1

10.5 STCs ....................................................................................................................... 10-1

10.6 Adding Relief for Items Installed After Type Certification ...................................... 10-2

10.7 Items Needed for Evaluation of Design Changes ..................................................... 10-3

Chapter 11. Nonessential Equipment and Furnishings (NEF) Program .................................... 11-1

11.1 Definition................................................................................................................... 11-1

11.2 Background ............................................................................................................... 11-1

11.3 The NEF Program Under § 91.213(a) ....................................................................... 11-1

11.4 Deferral Authority ..................................................................................................... 11-2

11.5 NEF Program Development ...................................................................................... 11-3

11.6 Required NEF Program Contents .............................................................................. 11-3

11.7 NEF Program Approval............................................................................................. 11-4

11.8 Criteria for Selection of NEF Items .......................................................................... 11-4

11.9 NEF Deferral Process ................................................................................................ 11-5

Chapter 12. Configuration Deviation List (CDL) ...................................................................... 12-1

12.1 Purpose of the CDL ................................................................................................... 12-1

12.2 Development ............................................................................................................. 12-1

12.3 CDL Versus MEL ..................................................................................................... 12-1

12.4 CDL Management Program ...................................................................................... 12-2

List of Figures

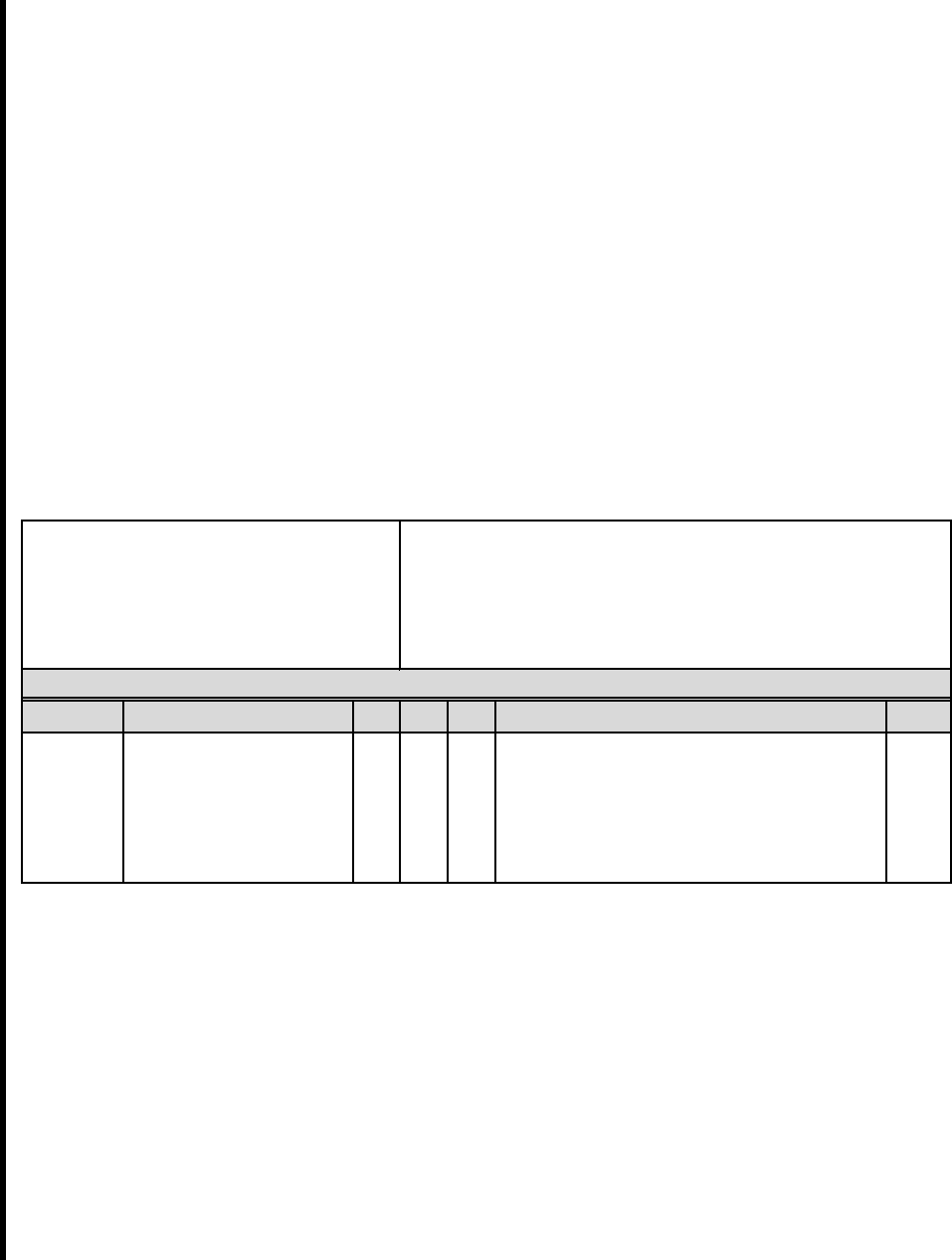

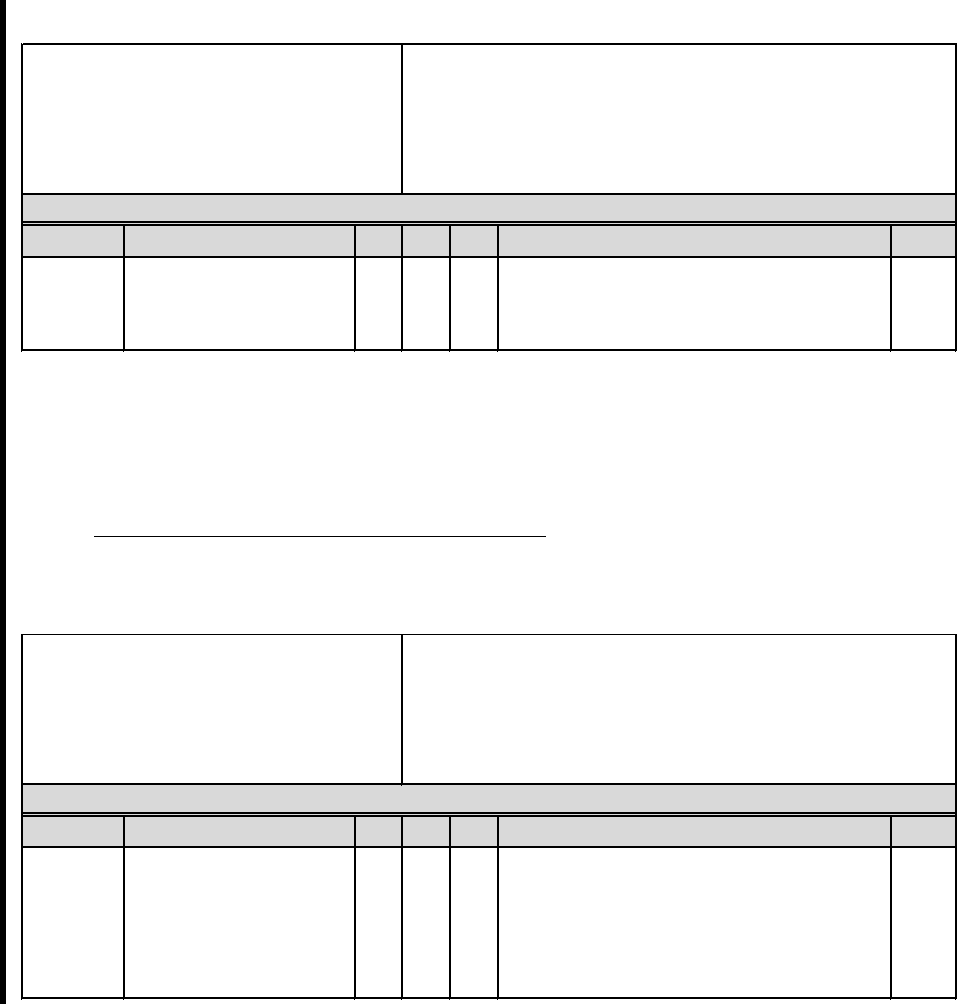

Figure 2-1. Example MMEL ATA/JASC Coded System Section Page .................................... 2-2

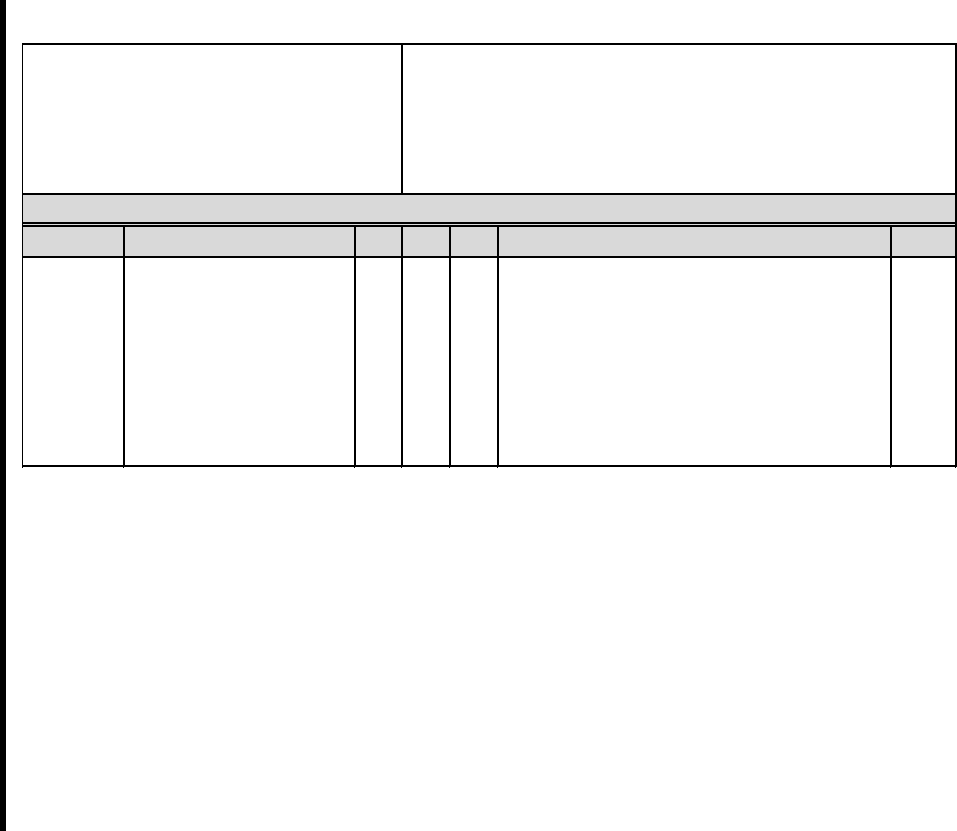

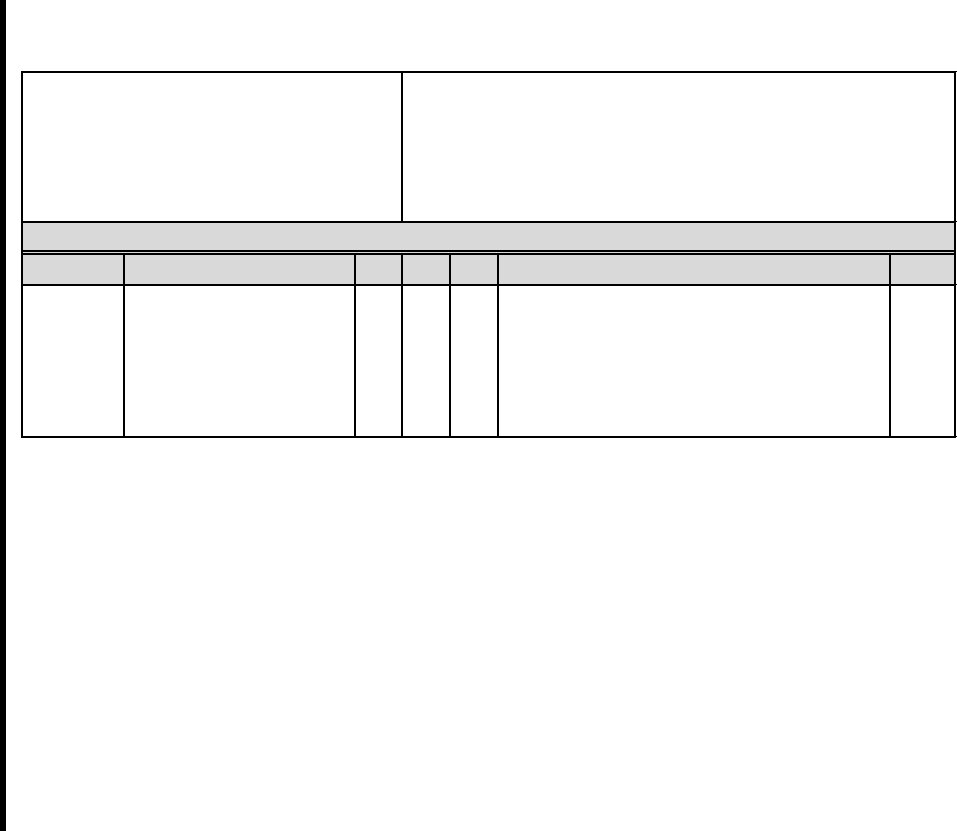

Figure 2-2. Sample Global Change Header Box ....................................................................... 2-4

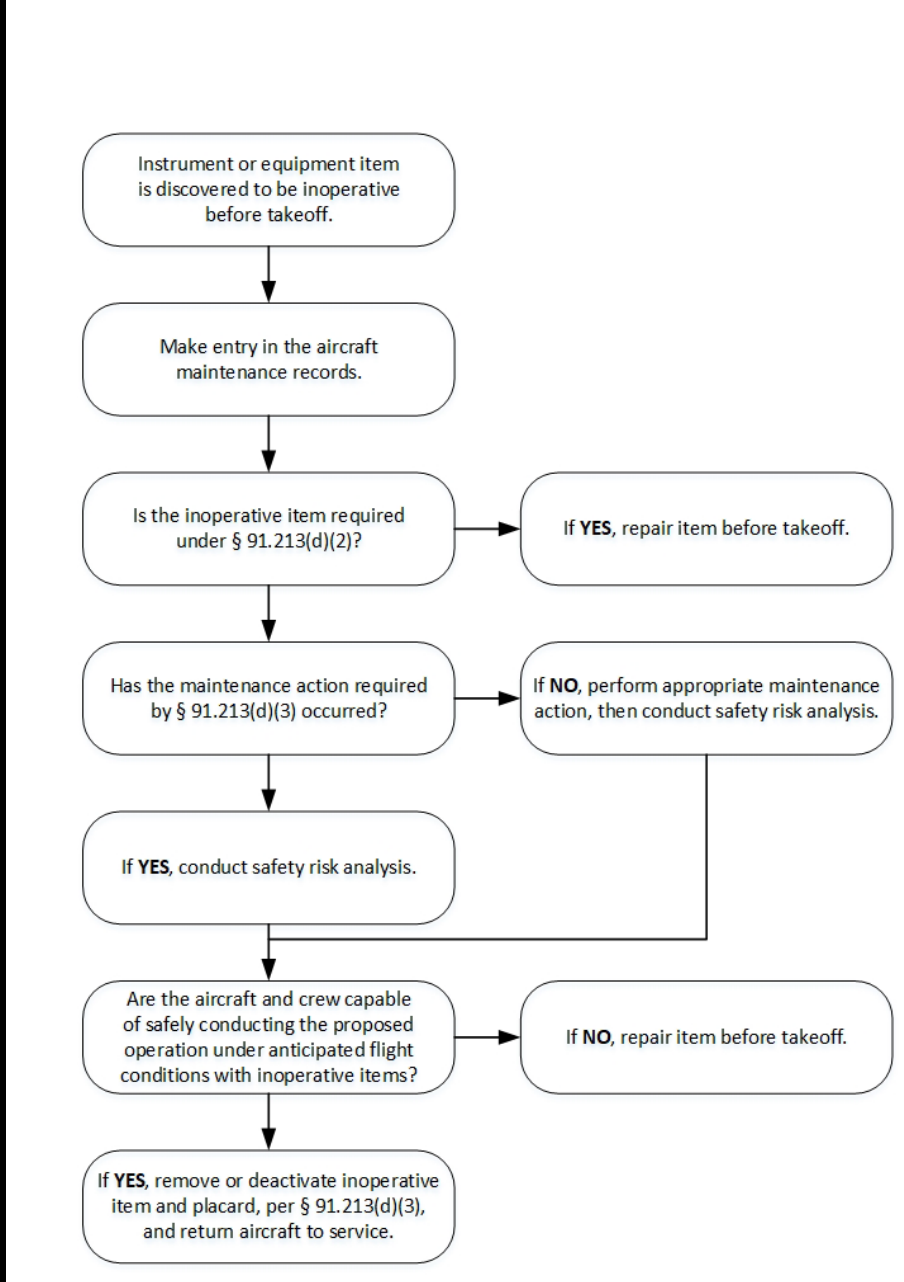

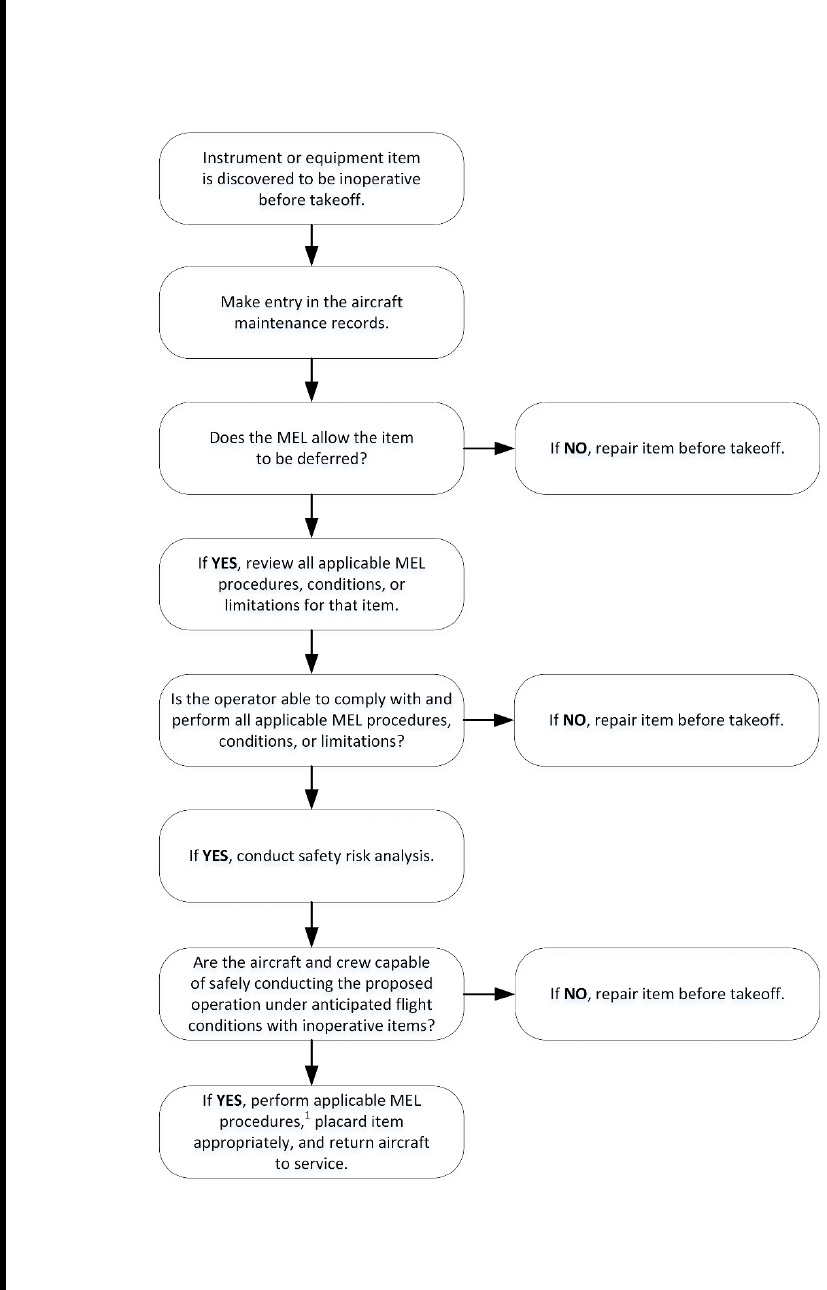

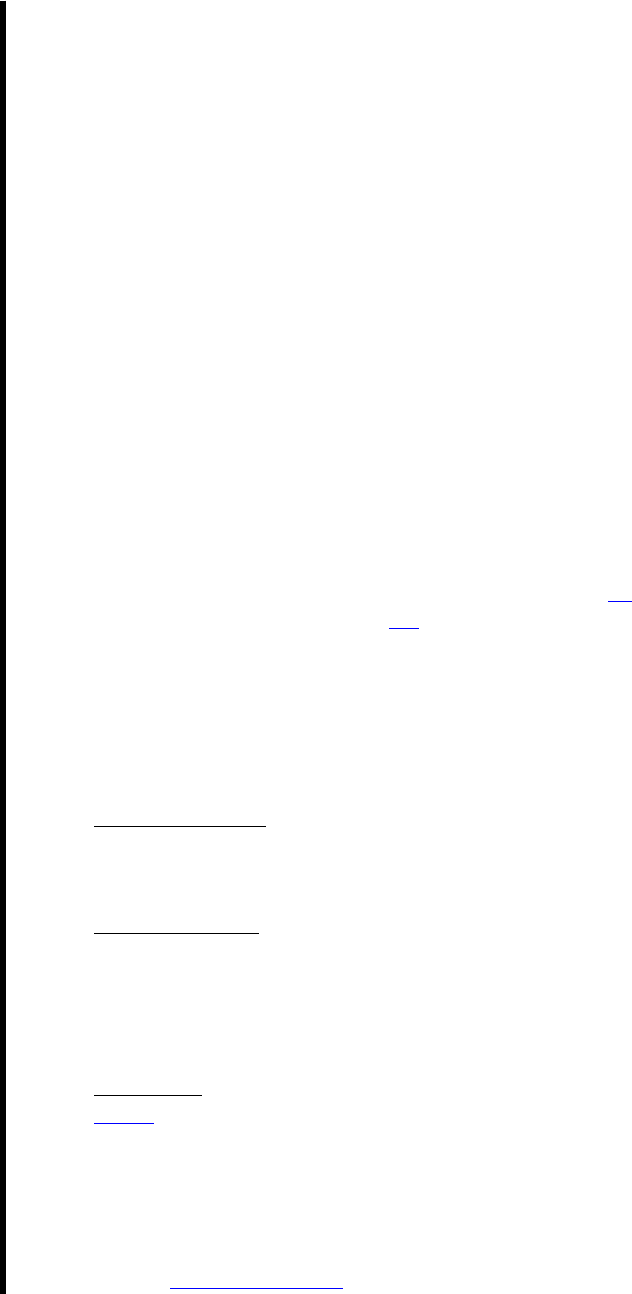

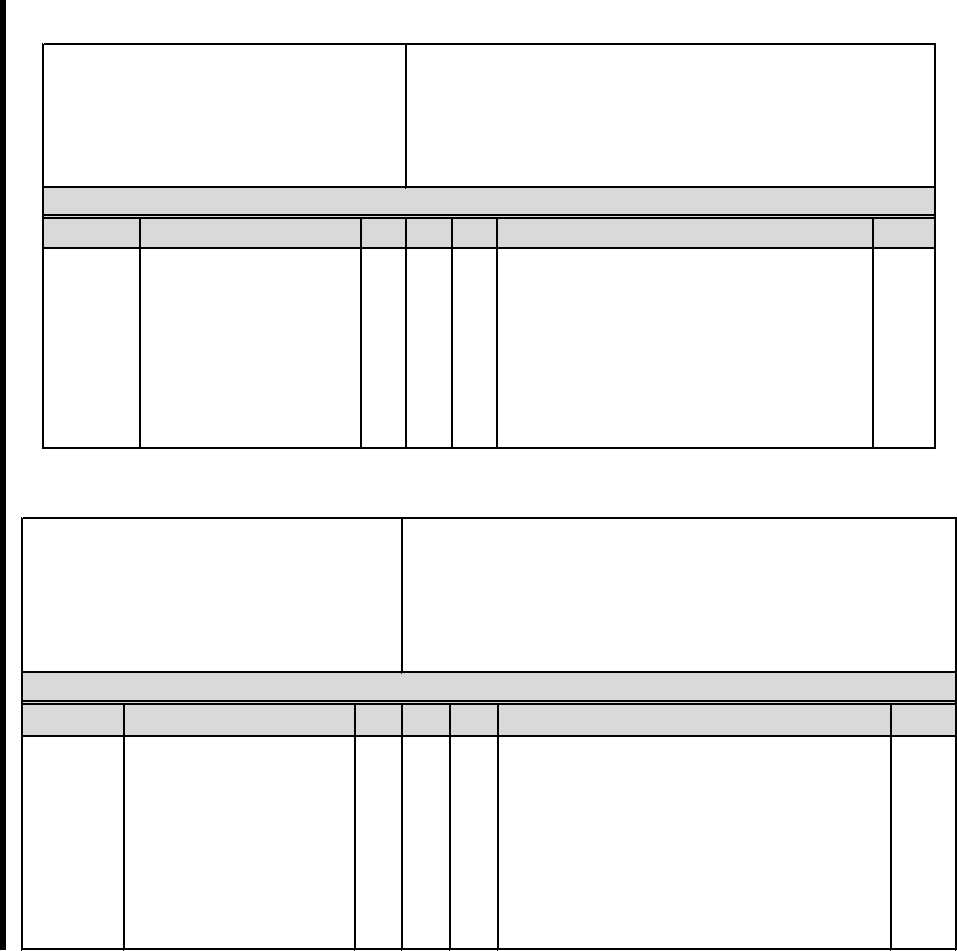

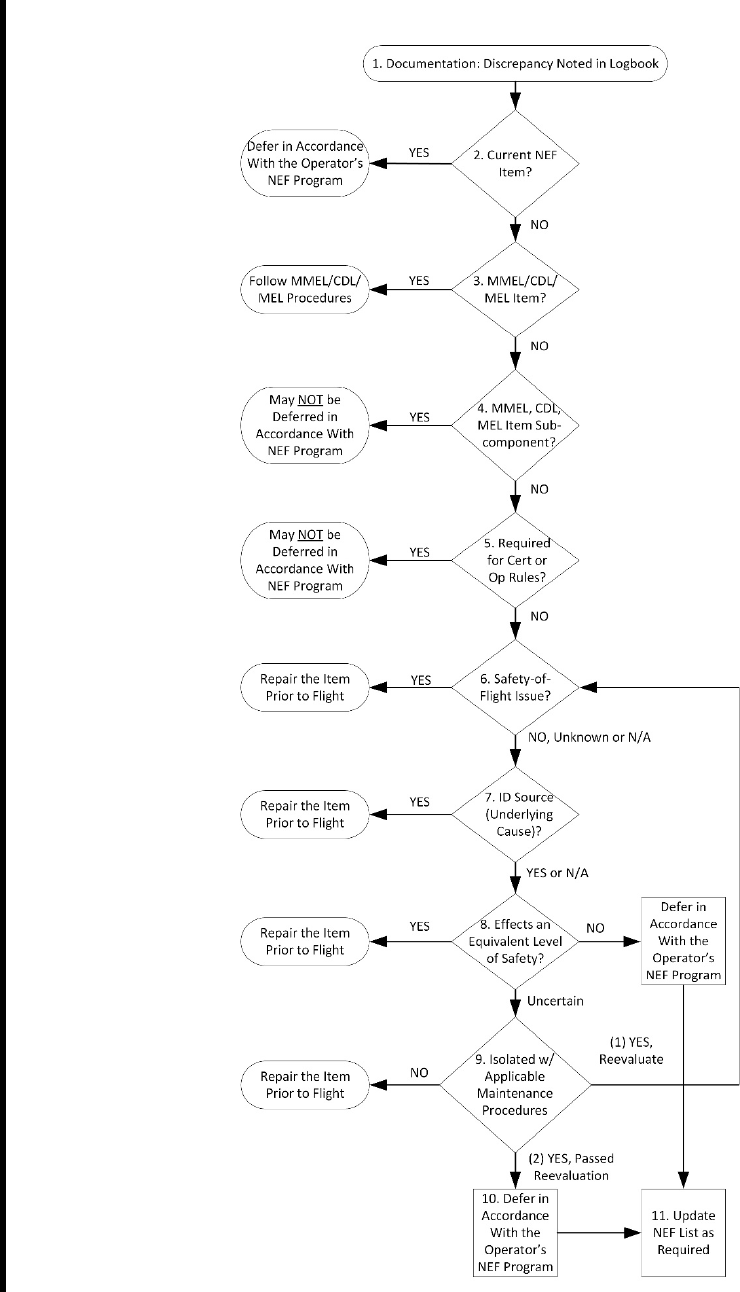

Figure 4-1. PIC Decision Sequence ........................................................................................... 4-4

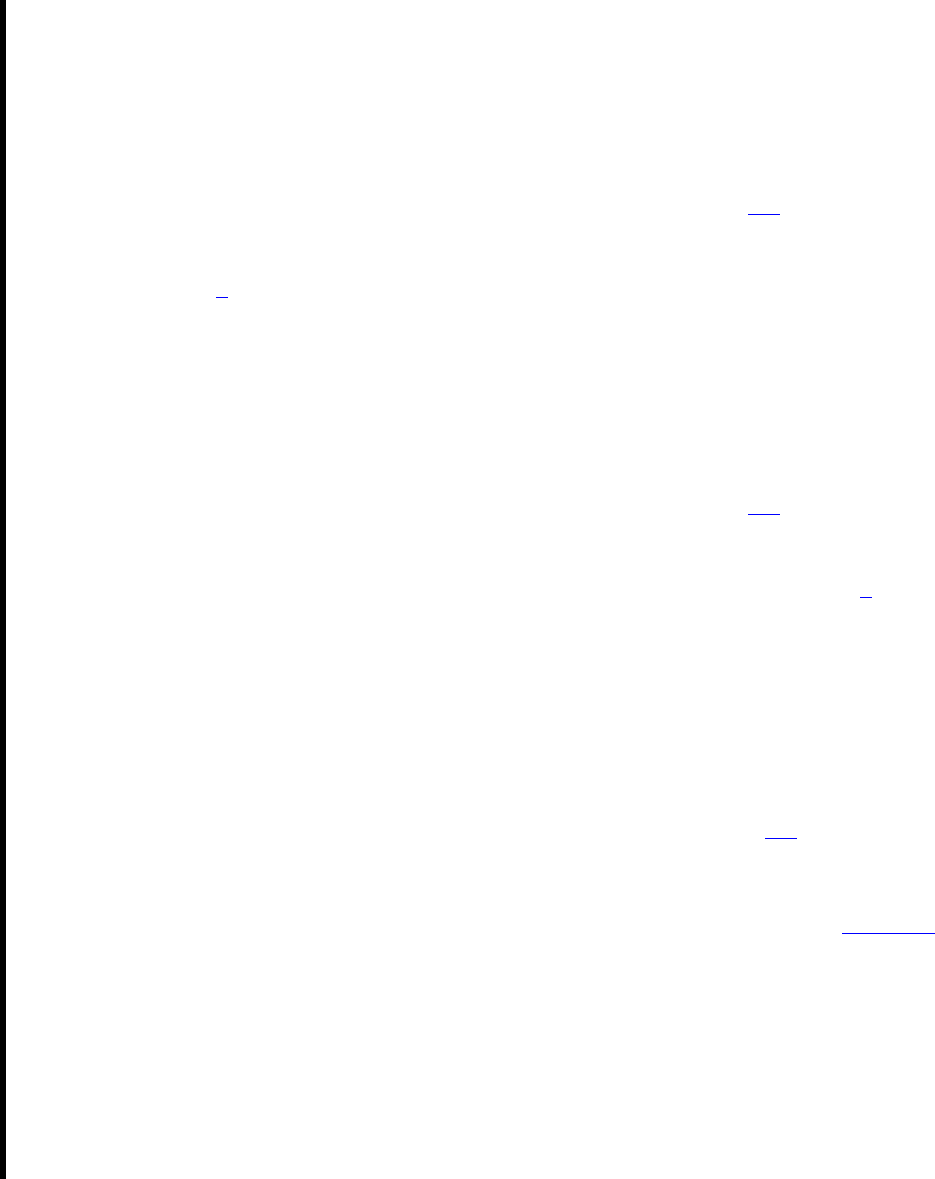

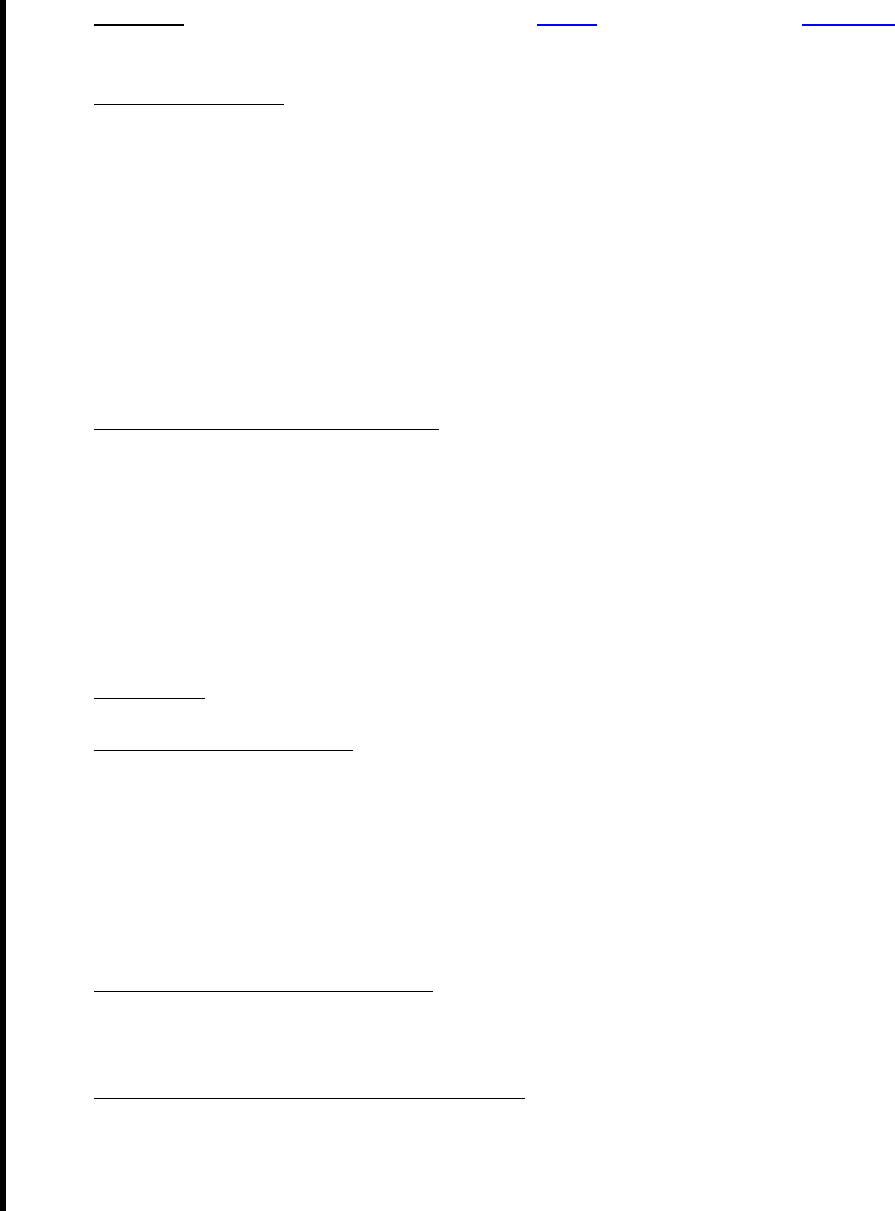

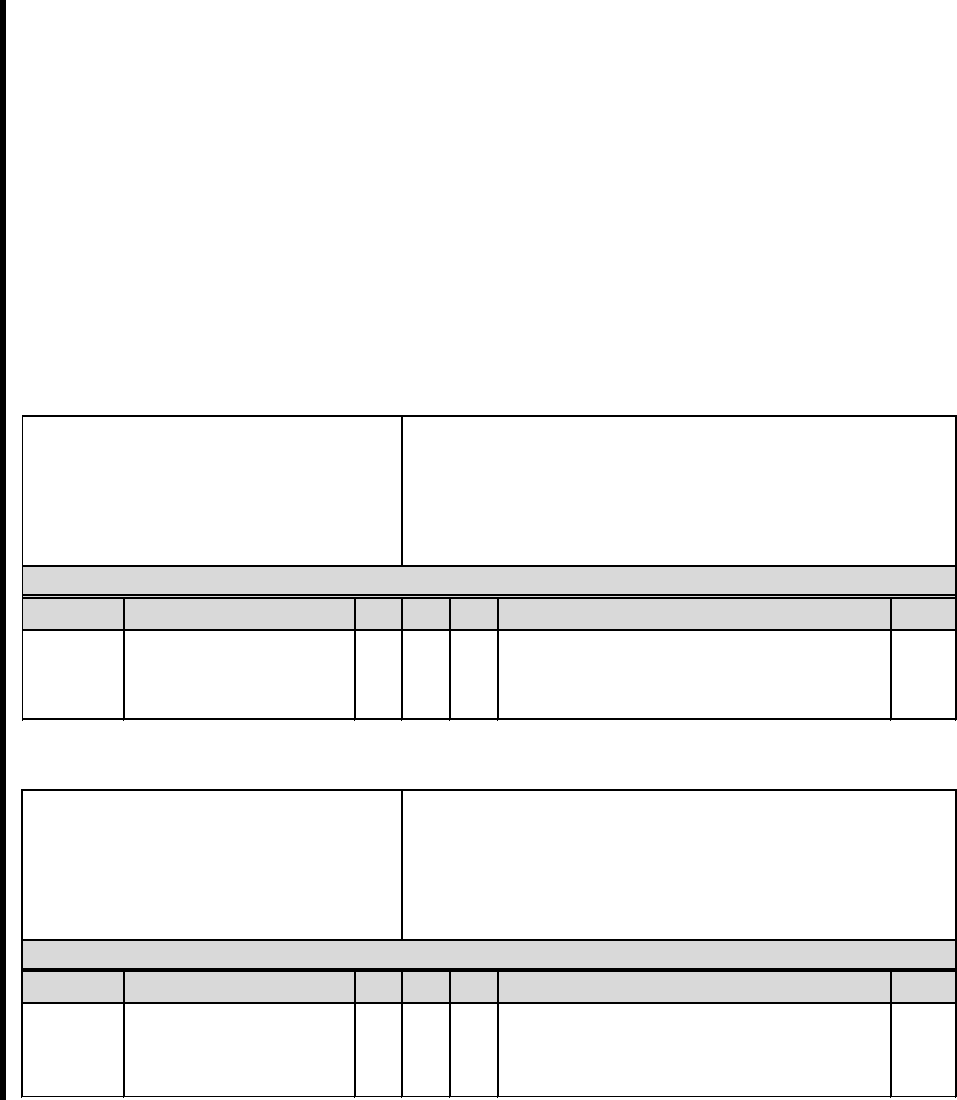

Figure 5-1. PIC Decision Sequence ........................................................................................... 5-4

Figure 6-1. Sample LOA D095 Request Letter ......................................................................... 6-2

Figure 6-2. Sample LOA D195 Request Letter for an Operator-Developed MEL That Conforms

to the Content Described in AC 91-67 .................................................................... 6-3

Figure 6-3. Sample LOA D195 Request Letter for an Operator-Developed MEL That Does Not

Conform to the Content Described in AC 91-67 .................................................... 6-4

Figure 7-1(a). Example MMEL “As Required by 14 CFR” Statement ...................................... 7-3

DATE “DRAFT” AC 91-67A

v

Figure 7-1(b). Example Procedures Document “As Required by 14 CFR” Regulatory

Reference or Requirement/Limitation ................................................................. 7-4

Figure 7-2(a). Example 1 MMEL Maintenance (M) and Operations (O) Symbols and

Provisos ................................................................................................................ 7-4

Figure 7-2(b). Example 1 Procedures Document Maintenance (M) and Operations (O)

Procedures ............................................................................................................ 7-4

Figure 7-3(a). Example 2 MMEL Maintenance (M) Symbol and Proviso ................................. 7-5

Figure 7-3(b). Example 2 Procedures Document Maintenance (M) Procedure .......................... 7-5

Figure 8-1(a). Example MMEL General “As Required by 14 CFR” Statement ........................ 8-8

Figure 8-1(b). Example MEL Specific “As Required by 14 CFR” Regulatory Reference......... 8-8

Figure 8-1(c). Example MEL Specific “As Required by 14 CFR” Requirement/Limitation ..... 8-9

Figure 8-2(a). Example 1 MMEL General Maintenance (M) and Operations (O) Symbols

and Provisos ......................................................................................................... 8-9

Figure 8-2(b). Example 1 MEL Specific Maintenance (M) and Operations (O) Symbols

and Provisos ....................................................................................................... 8-10

Figure 8-2(c). Example 1 Procedures Document Maintenance (M) and Operations (O)

Procedures .......................................................................................................... 8-10

Figure 8-3(a). Example 2 MMEL General Maintenance (M) Symbol and Proviso ................. 8-11

Figure 8-3(b). Example 2 MEL Specific Maintenance (M) Symbol and Proviso .................... 8-11

Figure 8-3(c). Example 2 Procedures Document Maintenance (M) Procedure ........................ 8-12

Figure 8-4(a). Example 3 MMEL General Operation (O) Symbol and Proviso ....................... 8-12

Figure 8-4(b). Example 3 MEL Specific Operations (O) Symbol and Proviso ........................ 8-12

Figure 8-4(c). Example 3 Procedures Document Operations (O) Procedure ............................ 8-13

Figure 11-1. Required NEF MEL Proviso for an Operator’s NEF Program .......................... 11-4

Figure 11-2. NEF Item Selection Criteria Elements Flowchart ............................................. 11-7

DATE “DRAFT” AC 91-67A

1-1

CHAPTER 1. INTRODUCTION

1.1 Purpose of This Advisory Circular (AC). This AC describes acceptable ways in which

an aircraft can be operated under Title 14 of the Code of Federal Regulations (14 CFR)

part 91, 133, or 137 (including part 91 operations conducted by parts 141 and 142

certificate holders (CH)) with certain inoperative instruments and equipment items that

are not essential for safe operations, in accordance with part 91, § 91.213. The methods

described are not the only means to comply with § 91.213. The Federal Aviation

Administration (FAA) will consider other means of compliance an operator may present.

1.1.1 Effects of Guidance. The contents of this document do not have the force and effect of

law and are not meant to bind the public in any way, and the document is intended only

to provide information to the public regarding existing requirements under the law or

agency policies. While using the means of compliance described in this AC is not

mandatory, an operator that voluntarily elects to use the means of compliance described

in this AC must follow, in all respects, the terms, conditions, and processes described in

the AC. The use of terms such as “shall” and “must” throughout the AC do not impose

any regulatory requirement.

1.2 Audience. This AC applies only to aircraft operated under parts 91, 133, and 137

(including part 91 operations conducted by parts 141 and 142 CHs) with certain

inoperative instruments and equipment.

Note: Unless otherwise stated, the term “operator,” used throughout this AC,

applies to part 91 operators, parts 133 and 137 CHs, and part 141 pilot schools or

provisional pilot schools. This AC uses the singular term “operator” for

simplicity.

1.2.1 Applicability. This AC does not apply to part 91 subpart K (part 91K) program managers

or CHs under 14 CFR part 121, 125 (including part 125 Letter of Deviation Authority

(LODA) holders), or 135. These operators are required to comply with their approved

minimum equipment list (MEL), even when the operation is conducted under part 91.

Refer to § 91.213(c).

1.2.2 Foreign Air Carriers and Foreign Operators of U.S. Registered Aircraft Engaged in

Common Carriage (14 CFR Part 129). Foreign air carriers and foreign operators of U.S.

registered aircraft engaged in common carriage should refer to AC 129-4, Maintenance

Programs for U.S. Registered Aircraft Operated Under 14 CFR Part 129, for information

regarding their MELs.

1.3 Where You Can Find This AC. You can find this AC on the FAA’s website at

https://www.faa.gov/regulations_policies/advisory_circulars and the Dynamic Regulatory

System (DRS) at https://drs.faa.gov.

1.4 What This AC Cancels. AC 91-67, Minimum Equipment Requirements for General

Aviation Operations Under FAR Part 91, dated June 18, 1991, was canceled on

November 3, 2017.

DATE “DRAFT” AC 91-67A

1-2

1.5 Related 14 CFR Sections. All regulatory references in this AC are found in 14 CFR

unless otherwise indicated. The following 14 CFR sections are related to this AC. You

can download the full text of these regulations at the U.S. Government Publishing Office

(GPO) Electronic Code of Federal Regulations (e-CFR) website at https://ecfr.gov. You

can order a paper copy by sending a request to the U.S. Superintendent of Documents,

U.S. Government Publishing Office; by calling the telephone number 202-512-1800; or

by sending a request by facsimile at 202-512-2104.

• Part 21, §§ 21.19, 21.197, and 21.199.

• Part 43, §§ 43.3, 43.7, 43.9, 43.11, and 43.13.

• Part 91, §§ 91.7, 91.205, 91.213, 91.405, 91.417, and 91.501.

1.6 Related Documents (current editions).

• Master Minimum Equipment List (MMEL) Policy Letter (PL)-25, MMEL/MEL

Definitions.

• MMEL PL-36, 14 CFR Part 91 MEL Approval and Preamble.

• AC 43-9, Maintenance Records.

• AC 43-12, Preventive Maintenance.

• AC 91-70, Oceanic and Remote Continental Airspace Operations.

1.7 Background. The airworthiness certification of an aircraft is conditioned on the aircraft

conforming to its type certificate (TC) and being in a condition for safe operation. While

items installed in an aircraft must be operative for the aircraft to conform to its TC, an

approved MEL allows an operator to operate the aircraft with certain items inoperative.

An approved MEL, as authorized by a Letter of Authorization (LOA) under § 91.213(a),

constitutes an approved change to the type design without requiring recertification.

1.7.1 Airworthiness. Under § 91.7, an operator cannot operate an aircraft unless it is in an

airworthy condition. As noted above, to be airworthy, the aircraft must conform to its TC

and be in a condition for safe operation. An inoperative item present on the aircraft would

result in a violation of § 91.7, unless the inoperative item or equipment is listed on the

operator’s approved MEL, in accordance with § 91.213. As such, compliance with all

applicable criteria of an MEL is necessary when taking advantage of the relief an MEL

provides; in the absence of such compliance, the FAA would not consider the aircraft

airworthy.

1.7.2 Acceptable Level of Safety (ALoS). The FAA developed the concept of the MEL after

recognizing that under certain circumstances, a flight or series of flights might occur

safely with certain inoperable instruments and equipment. In certain specific situations,

an ALoS can be met because not all of an aircraft’s installed instruments and equipment

are necessary for every type of operation. For example, a flight that is not being

conducted in icing conditions would not require operable airframe deicing or anti-icing

equipment. Similarly, an aircraft that will not operate at night may receive relief from the

DATE “DRAFT” AC 91-67A

1-3

requirement to have an operable landing light. In other words, the MEL requirements and

related processes are independent from an aircraft’s operating requirements and an MEL

cannot authorize a deviation from operating rules.

1.7.3 Requirement for Items to be Operative. All items related to the airworthiness of the

aircraft that are not included in an approved MEL are required to be operative in

accordance with the aircraft’s TC. An MEL does not include obviously required items,

such as wings, rudders, flaps, engines, landing gear, etc. An aircraft is not airworthy

when any item that is not included in the MEL is inoperative.

1.7.4 Repair Inoperative Items at Earliest Opportunity. The MEL is intended to permit

operations with inoperative items of equipment for the minimum period of time necessary

until repairs can be accomplished. It is important that repairs be accomplished at the

earliest opportunity to return the aircraft to its design level of safety and reliability.

1.7.5 MEL Development. The MEL is developed from an MMEL for the aircraft type. The

operator uses the MMEL as the baseline to develop the MEL and the operational and

maintenance procedures and lists the items installed in the operator’s aircraft. The MEL

is developed by the operator for their particular type of operation (i.e., instrument flight

rules (IFR), visual flight rules (VFR), Category (CAT) II, over water, etc.). The MEL is

approved by the responsible Flight Standards office.

1.8 Definitions and Terminology. For additional MMEL and MEL definitions, refer to

MMEL PL-25.

1.8.1 Airworthiness Directive (AD). ADs are legally enforceable regulations issued by the

FAA in accordance with 14 CFR part 39 to correct an unsafe condition in a product.

Part 39 defines a product as an aircraft, engine, propeller, or appliance.

1.8.2 Air Transport Association of America (ATA)/Joint Aircraft System/Component (JASC)

Coded System Section Components. MMEL system sections are organized by aircraft

system according to the ATA or JASC coded numbering system. MMEL system numbers

use the ATA/JASC codes that are standardized for each aircraft system. The ATA/JASC

numbering system provides an industrywide standard for numbering aircraft systems and

is relevant for all aircraft. ATA changed its name to Airlines for America (A4A) in 2011;

however, the acronym “ATA” is still used for coded aircraft systems. The acronyms

“ATA” and “A4A” are considered interchangeable. The alternate format for aircraft

system coding is the JASC codes, which are a modified version of the ATA codes.

1.8.3 Aircraft Evaluation Division (AED). The inspectors in AED serve as technical subject

matter experts for operational and engineering activities of the FAA’s Flight Standards

Service (FS). These inspectors coordinate and assist with aircraft certification and

continued airworthiness programs and serve as a liaison with the responsible Aircraft

Certification Service office during the initial certification of an aircraft and throughout

the service life of the aircraft.

1.8.4 Configuration Deviation List (CDL). A CDL is a list of externally exposed aircraft parts

that may be missing for flight. A CDL allows continued operation with missing

DATE “DRAFT” AC 91-67A

1-4

externally exposed nonstructural parts by defining restrictions, limitations, or

performance penalties, while the aircraft remains airworthy. See Chapter 12 for

additional information on the CDL.

1.8.5 Deferral. The term “deferral” is used to describe the authorization for an operator to delay

repair and continue operating with a required item inoperative, under the authority of

their FAA-approved MEL. Authority to defer an inoperative item is subject to specific

conditions and limitations, as described in the associated proviso.

1.8.6 Dynamic Regulatory System (DRS). DRS is an FAA website that contains regulatory,

policy, and guidance information. DRS can be accessed at https://drs.faa.gov.

1.8.7 Flight Operations Evaluation Board (FOEB). An FOEB is comprised of technically

qualified specialists, engineering representatives, and aviation safety inspectors (ASI)

responsible for developing MMELs from the proposed MMEL provided by the aircraft

manufacturer. An aircraft MMEL is usually developed during initial aircraft certification.

FOEBs are also responsible for developing MMEL revisions. FOEBs coordinate with

internal and external stakeholders, such as the responsible Aircraft Certification Service

office, Flight Standards offices, aircraft and engine manufacturers, operators, and

private-sector groups.

1.8.8 Global Change (GC). A GC is newly developed or changed relief for an item, usually

applicable to numerous MMELs (hence “global”) to allow operators to obtain MEL relief

prior to the release of a revised MMEL. Incorporation of a GC into an operator’s MEL is

optional until the GC is incorporated in the aircraft’s MMEL. GCs may be used to

provide immediate relief for items required by a new regulatory requirement, policy

change, or new technology.

1.8.9 Kinds of Operations Equipment List (KOEL). Aircraft certificated under 14 CFR part 23

or 27 may have a KOEL. The KOEL specifies the kinds of operations (e.g., VFR, IFR,

day, or night) in which the aircraft can be operated. The KOEL also indicates the

installed equipment that may affect any operating limitation. Although the certification

rules require this information, there is no standard format; consequently, the

manufacturer may furnish it in various ways. Inoperative equipment, when required by

the KOEL for a particular type of operation (e.g., VFR, IFR, day, or night), may not be

deferred for that operation under § 91.213.

1.8.10 Letter of Authorization (LOA). The term “LOA,” used throughout this AC, refers to an

operator-specific LOA, which is the MEL-authorizing document containing conditions

and limitations the operator must comply with in order to conduct aircraft operations with

specific inoperative items. When used in this AC, the term “LOA” refers to all LOAs

issued under the provisions of § 91.213(a) to part 91 operators, part 133 rotorcraft

external-load operators, part 137 agricultural aircraft operators, and part 141 pilot schools

or provisional pilot schools.

Note: The part 142 training specification (TSpec) D095 has been

decommissioned. Part 142 training centers holding TSpec A003, Aircraft

DATE “DRAFT” AC 91-67A

1-5

Authorization, and seeking MEL authorization must do so under the appropriate

operating rule (e.g., part 91, 121, or 135).

1.8.11 Maintenance (M) Procedure. The (M) symbol indicates a specific maintenance procedure

that must be accomplished prior to operation with the listed item inoperative. Normally,

(M) procedures are accomplished by qualified maintenance personnel; however, other

personnel may be qualified and authorized to perform certain functions. Procedures

requiring specialized knowledge or skill, or requiring the use of tools or test equipment,

should be accomplished by maintenance personnel. The satisfactory accomplishment of

all (M) procedures, regardless of who performs them, is the responsibility of the aircraft

operator. Appropriate procedures are required as a part of the aircraft operator’s MEL.

See paragraph 5.4, Performing (M) and (O) Procedures.

1.8.12 Master Minimum Equipment List (MMEL).

1.8.12.1 The term “MMEL,” used throughout this AC, means an FAA-approved,

aircraft make, model, and series (M/M/S)-specific master list of aircraft

instrument and equipment items that may be inoperative under certain

operational conditions, while maintaining the airworthiness of the aircraft and

providing an ALoS. An MMEL is the baseline document used by operators to

develop their own aircraft-specific MEL. Operators may download MMELs

from the “MMELs and AED Guidance Documents” section in DRS at

https://drs.faa.gov.

1.8.12.2 The United States may enter a Bilateral Aviation Safety Agreement (BASA)

with a foreign government when there is a need for technical cooperation with

the foreign government’s Civil Aviation Authority (CAA), and if the foreign

authority’s civil aviation safety oversight is substantially comparable to the

FAA’s. BASAs are carried out through associated implementation procedures.

Refer to country-specific BASAs for MMEL considerations relating to foreign

type-certificated aircraft validated under Implementation Procedures for

Airworthiness (IPA). The BASAs and associated IPAs may be found at

https://www.faa.gov/aircraft/air_cert/international/bilateral_agreements/.

1.8.13 Minimum Equipment List (MEL). The term “MEL,” used throughout this AC, means a

document listing items that may be inoperative during flight for a specific aircraft or a

fleet of aircraft. Operation of the aircraft under the MEL is authorized by an operator

specific LOA. As provided in § 91.213(a)(2), an MEL and the associated LOA constitute

a Supplemental Type Certificate (STC) for the aircraft. Operators will base their MEL on

the MMEL applicable to the aircraft M/M/S. An operator’s MEL may be more restrictive

than the MMEL, but it will not be less restrictive. Unless specified otherwise, the term

“MEL,” used throughout this AC, refers to both: (1) the MEL approval under LOA D095,

MMEL Used as an MEL, consisting of an MMEL and a procedures document, and (2)

the MEL approval under LOA D195, Minimum Equipment List (MEL), consisting of an

operator-developed MEL. When required for clarity, this AC will distinguish between an

MEL approval under LOA D095 or D195 by using the terms “procedures document,” or

“operator-developed MEL,” respectively.

DATE “DRAFT” AC 91-67A

1-6

Note: MEL approvals under LOA D095 meet the International Civil Aviation

Organization (ICAO) MEL requirements of Annex 6, Parts II and III. However,

some CAAs may not accept LOA D095 as a valid MEL approval.

1.8.14 MMEL Policy Letters (PL). PLs clarify FAA MMEL policy regarding specific kinds of

equipment that may be deferred. While developing its MEL, an operator may need to

refer to one or more aircraft or equipment-specific PLs with a GC designation, as these

PLs may provide additional relief for items until the MMEL is revised. Operators may

download PLs from the “MMELs and AED Guidance Documents” section in DRS at

https://drs.faa.gov.

1.8.15 Make, Model, and Series (M/M/S). M/M/S is a common abbreviation used when

referring to a manufacturer’s particular model or type and series of given aircraft.

1.8.16 Nonessential Equipment and Furnishings (NEF) Program. An operator’s MEL program

may also include an NEF program that allows relief for nonessential items. An NEF

program allows operators to use the authority granted by their MEL LOA to provide

relief for nonessential items located throughout the aircraft. See Chapter 11 for additional

information on an NEF program.

1.8.17 Operational Control. As defined in 14 CFR part 1, § 1.1, operational control, “with

respect to a flight, means the exercise of authority over initiating, conducting or

terminating a flight.”

1.8.18 Operations (O) Procedure. The (O) symbol indicates a specific operations procedure that

must be accomplished prior to operation with the listed item inoperative. Normally, these

procedures are accomplished by the flightcrew; however, other personnel may be

qualified and authorized to perform certain functions. These procedures may be required

for flight planning purposes, or they may require action by the flightcrew. Additionally,

MEL items affecting the aircraft Weight and Balance (W&B) and cargo loading may

require procedures for additional personnel, such as those involved with aircraft load

control. The satisfactory accomplishment of all (O) procedures, regardless of who

performs them, is the responsibility of the aircraft operator. Appropriate procedures are

required as a part of the aircraft operator’s MEL. See paragraph 5.4.

1.8.19 Procedures Document. The procedures document is based on the MMEL applicable to

the aircraft M/M/S. The procedures document, the MMEL, and the MEL LOA D095

together constitute an approved MEL. The procedures document contains:

• The name(s) of the operator(s),

• The aircraft serial and registration numbers (or “Fleet”),

• The aircraft M/M/S,

• The MMEL revision number on which the MEL is based,

• (M) and (O) procedures that correspond with the (M) and (O) provisos listed in the

MMEL,

DATE “DRAFT” AC 91-67A

1-7

• A list of all MMEL items that contain the statement “as required by 14 CFR,”

• All applicable definitions, per MMEL PL-25, and

• The preamble, per current MMEL PL-36.

1.8.20 Principal Base of Operations. The term “principal base of operations” used throughout

this AC is the physical address where an operator or pilot school conducts business or

resides. It is a physical location where the FAA can contact the operator (i.e., a post

office box is not an acceptable principal base of operations). While the principal base of

operations may coincide with the place where the aircraft is located, this is not always the

case. Depending upon the applicable 14 CFR part, this location may be an operator’s

residence, business address, home base of operations, or a pilot school’s principal

business office. For simplicity, this AC uses the singular term “principal base of

operations” to refer to all these locations.

1.8.21 Principal Inspector (PI). PIs are FAA personnel, within the operator’s responsible Flight

Standards office, who are assigned primary responsibility for oversight of an operator’s

safety of operations. PIs specialize in the three general areas of aircraft operations

according to their qualifications, either as a Principal Avionics Inspector (PAI), Principal

Maintenance Inspector (PMI), or Principal Operations Inspector (POI). PIs have FAA

administrative authority to evaluate and approve an operator’s manuals, including the

MEL.

1.8.22 Responsible Flight Standards Office. The term “responsible Flight Standards office,”

used throughout this AC, refers to the Flight Standards office responsible for issuance

and oversight of all LOAs for the operator. This is typically the Flight Standards office

with a Service Area (SA) covering the location of the operator’s principal base of

operations. FAA office locations are available at

https://www.faa.gov/about/office_org/field_offices/fsdo/ and

https://www.faa.gov/about/office_org/field_offices/ifo.

1.8.23 Responsible Person (Part 91 Only). The term “Responsible Person,” used throughout this

AC, is the person who has legal authority to sign the LOA on behalf of a part 91 operator.

Such person should have ongoing knowledge of the operations of the aircraft. The

Responsible Person may be the individual who acts as operator or, if the operator is a

legal entity, an officer, employee, or person duly designated to act on behalf of the

operator. The person assumes responsibility for ensuring the operator complies with all

applicable regulations, requirements, limitations, and provisions. If the Responsible

Person relinquishes responsibility, the LOA is no longer valid.

1.8.24 Supplemental Type Certificate (STC). An STC is a TC issued by the FAA to a person

who applies for a major change to a type design when the proposed change does not

require an application for a new TC under § 21.19. The STC, which incorporates by

reference the related TC, approves not only the modification but also how that

modification affects the original design.

DATE “DRAFT” AC 91-67A

1-8

1.9 AC Feedback Form. For your convenience, the AC Feedback Form is the last page of

this AC. Note any deficiencies found, clarifications needed, or suggested improvements

regarding the contents of this AC on the Feedback Form.

DATE “DRAFT” AC 91-67A

2-1

CHAPTER 2. MASTER MINIMUM EQUIPMENT LIST (MMEL)

2.1 General.

2.1.1 MEL Is Based on an MMEL. An M/M/S-specific MMEL is the document on which an

operator will base their aircraft-specific MEL. MMELs are developed for most FAA

type-certificated aircraft in general service today. Most multiengine airplanes have an

MMEL specific to their type design (e.g., Mitsubishi MU-2B).

2.1.2 Generic Single Engine Airplane MMEL. The FOEB has developed a generic

single-engine airplane MMEL for single-engine airplanes that do not have an

M/M/S-specific MMEL. The generic single-engine airplane MMEL cannot be used for an

airplane that has its own M/M/S-specific MMEL. If an operator is using the generic

single-engine airplane MMEL, and an MMEL is subsequently published for that specific

make and model single-engine airplane, the operator’s MEL must be revised to conform

to the new M/M/S-specific MMEL within 90 calendar-days of new M/M/S-specific

MMEL publication.

Note: Operators base their MEL on the MMEL applicable to the aircraft M/M/S

or the generic single-engine airplane MMEL, as appropriate.

2.1.3 Items Listed in an MMEL. The MMEL includes those items of equipment related to

airworthiness and operating regulations and other items of equipment, which may be

inoperative, and yet maintain an ALoS by appropriate conditions and limitations; it does

not contain obviously required items, such as wings and rudders. Additionally, an MMEL

does not include items required to be operative by an AD, unless the AD specifically

allows for their inclusion.

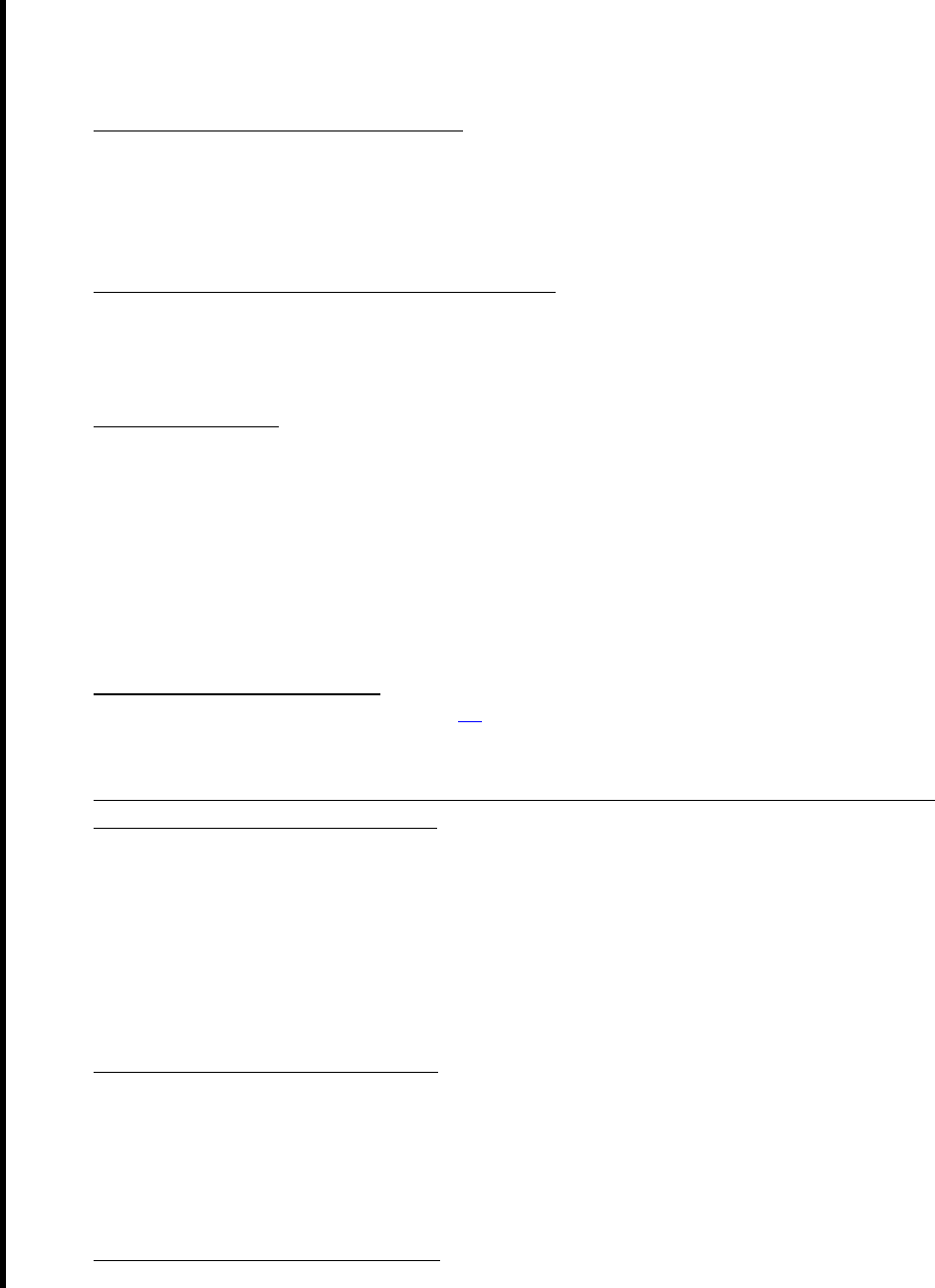

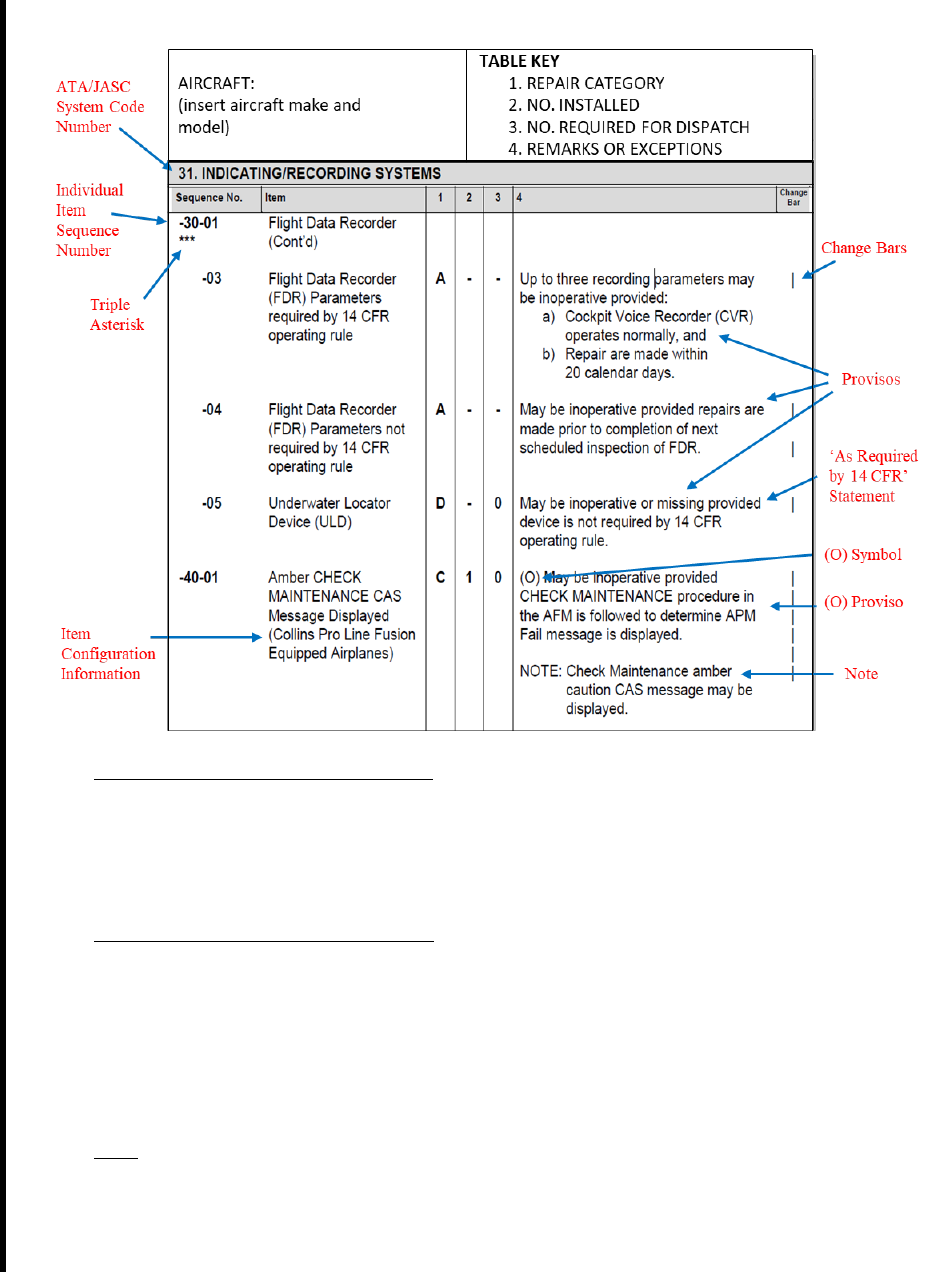

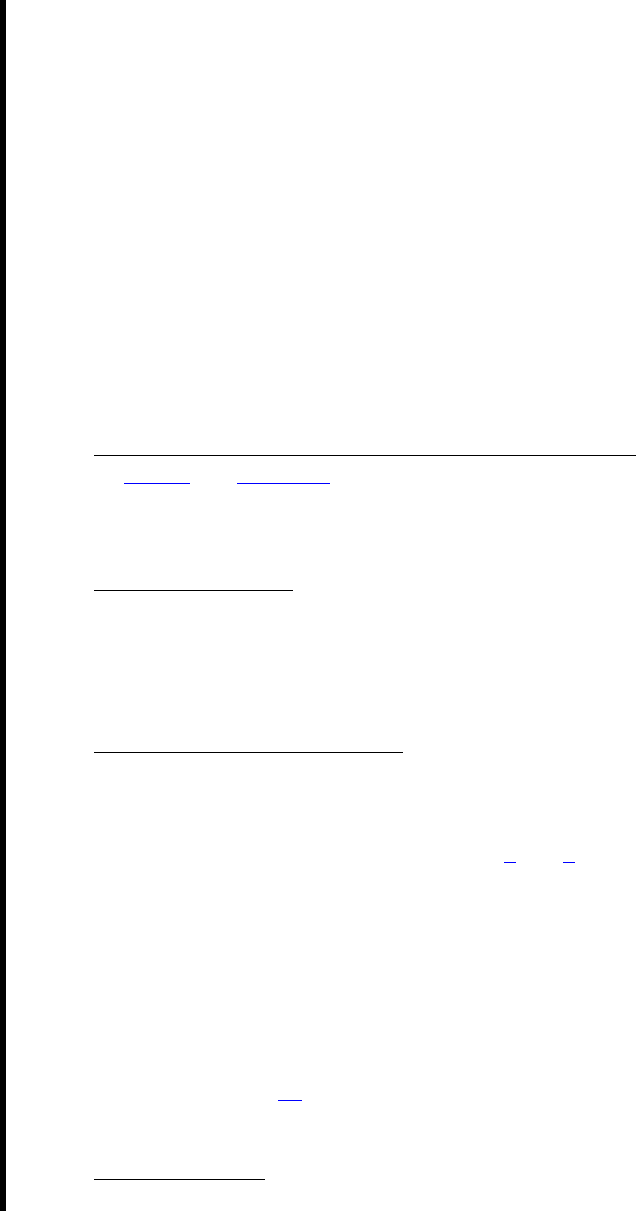

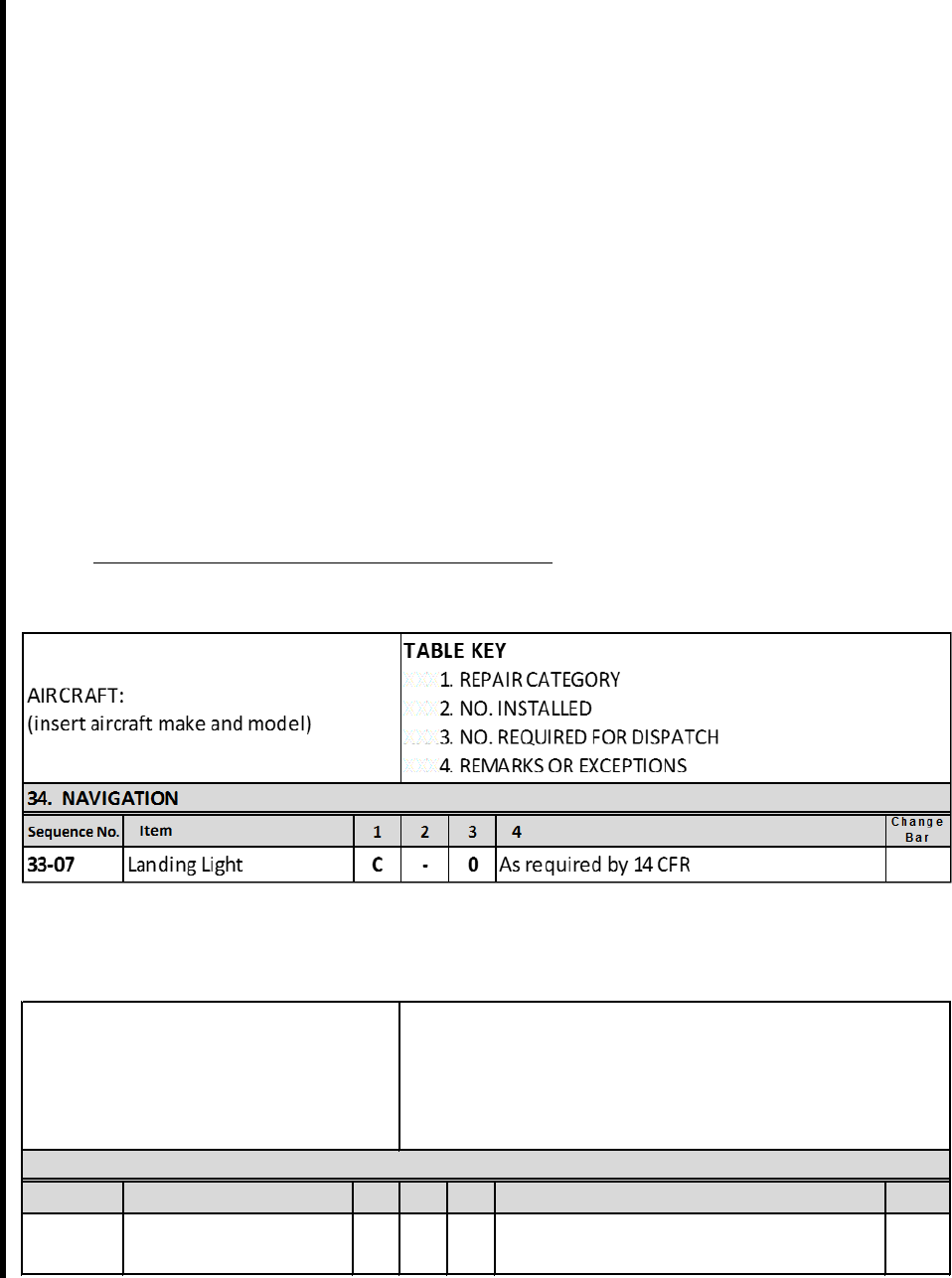

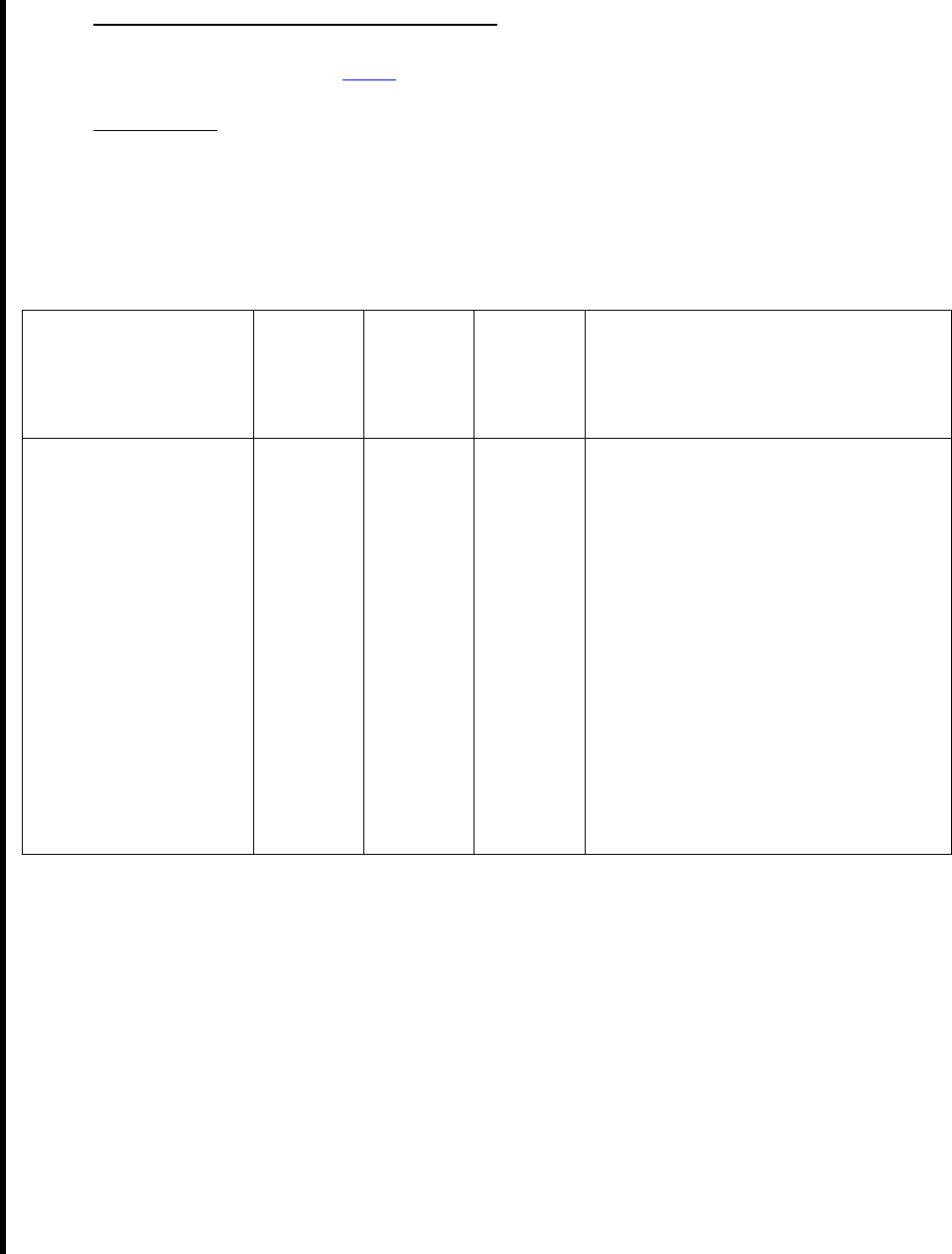

2.2 ATA/JASC Coded System Section Components. These sections are organized by

aircraft system according to the ATA or JASC coded numbering system (see Figure 2-1,

Example MMEL ATA/JASC Coded System Section Page) and contain the following

components:

DATE “DRAFT” AC 91-67A

2-2

Figure 2-1. Example MMEL ATA/JASC Coded System Section Page

2.2.1 ATA/JASC System Code Numbers. MMEL system numbers use the ATA or JASC codes

that are standardized for each aircraft system. The ATA numbering system provides an

industrywide standard for numbering aircraft systems and is relevant for all aircraft. The

alternate format for aircraft system coding is the JASC codes, which are a modified

version of the ATA codes.

2.2.2 Individual Item Sequence Numbers. Individual item sequence numbers are the unique

identification for each item within an ATA/JASC system category. The numbering

scheme may be modified to align with the aircraft operator’s specific MEL format and

may differ from the MMEL. They are not required to match ATA/JASC system code

numbers. A triple asterisk (***) below the sequence number in the first column of an

MMEL indicates that an item, which is not required by regulation, has been installed on

some models of a particular aircraft.

2.2.3 Item. An item is an instrument, piece of equipment, a system, component, or function of

an instrument, piece of equipment, system, or component on an aircraft. An MMEL may

contain multiple versions of particular items (e.g., flight deck display systems, navigation

equipment, or engine instrumentation) installed on different models or series of the

aircraft covered by the MMEL.

DATE “DRAFT” AC 91-67A

2-3

2.2.4 Repair Categories. The repair category intervals indicated by the letters A, B, C, and D in

column 1 of the MMEL are not applicable to an MEL approved under the provisions of

§ 91.213(a), but operators must comply with any provisos defining a repair interval

(e.g., flights, flight legs, cycles, hours, days, etc.). The operator must have any

inoperative items, which are permitted to be inoperative, either repaired, replaced,

removed, or inspected within the proviso-defined repair interval period, or at the next

required aircraft inspection, whichever comes first. Refer to § 91.405(c).

2.2.5 Number of Items Installed (Number Installed). Column 2 of an MMEL lists the number

(quantity) of the specified item normally installed on the aircraft. This number typically

represents the aircraft configuration used to develop the aircraft MMEL.

2.2.6 Variable Number Installed. A dash (-) for the number installed indicates a variable

number (quantity) of the installed item.

2.2.7 Number Required for Dispatch. Column 3 of an MMEL reflects the minimum number

(quantity) of items required to be operable for flight, provided the conditions specified in

the “Remarks or Exceptions” are met.

2.2.8 Variable Number of Items Required for Dispatch. A dash (-) indicates a variable number

required for dispatch.

2.2.9 Remarks or Exceptions. Column 4 includes provisos, notes, “as required by 14 CFR”

statements, and Maintenance (M) and Operations (O) symbols. Some MMEL “Remarks

or Exceptions” are intentionally general to accommodate a variety of operators and

operating rules.

2.3 Obtaining a Current MMEL. Operators may download MMELs from the “MMELs and

AED Guidance Documents” section in DRS at https://drs.faa.gov.

2.4 Aircraft for Which No MMEL Has Been Developed. Some aircraft, for which no

MMEL has been developed, may be operated under the provisions of § 91.213(d).

Note 1: Operators of single-engine reciprocating and turbine-powered airplanes

that do not have an MMEL for their specific M/M/S may use the generic

single-engine airplane MMEL.

Note 2: An operator may not operate an aircraft for which the FAA issued an

original experimental Airworthiness Certificate with inoperative items unless

specifically authorized in the aircraft’s operating limitations.

2.5 MMEL PLs. MMEL PLs communicate FAA policy for matters related to the

development and approval of MMELs and MELs. The primary audience for PLs is the

FOEB Chair and members. However, sometimes PLs apply to operators and are specific

to MEL considerations.

2.5.1 Mandatory MMEL PLs. Operators must include applicable information from MMEL

PL-25 (definitions) and MMEL PL-36 (preamble) in their MEL. See Chapters 7 and 8 for

DATE “DRAFT” AC 91-67A

2-4

additional information. Except for MMEL PL-25 and PL-36, or unless specifically

mandated in the PL, an operator is not required to include MMEL PL information in their

MEL.

2.5.2 Where to Find MMEL PLs. Operators may download MMEL PLs from the “MMELs and

AED Guidance Documents” section in DRS at https://drs.faa.gov.

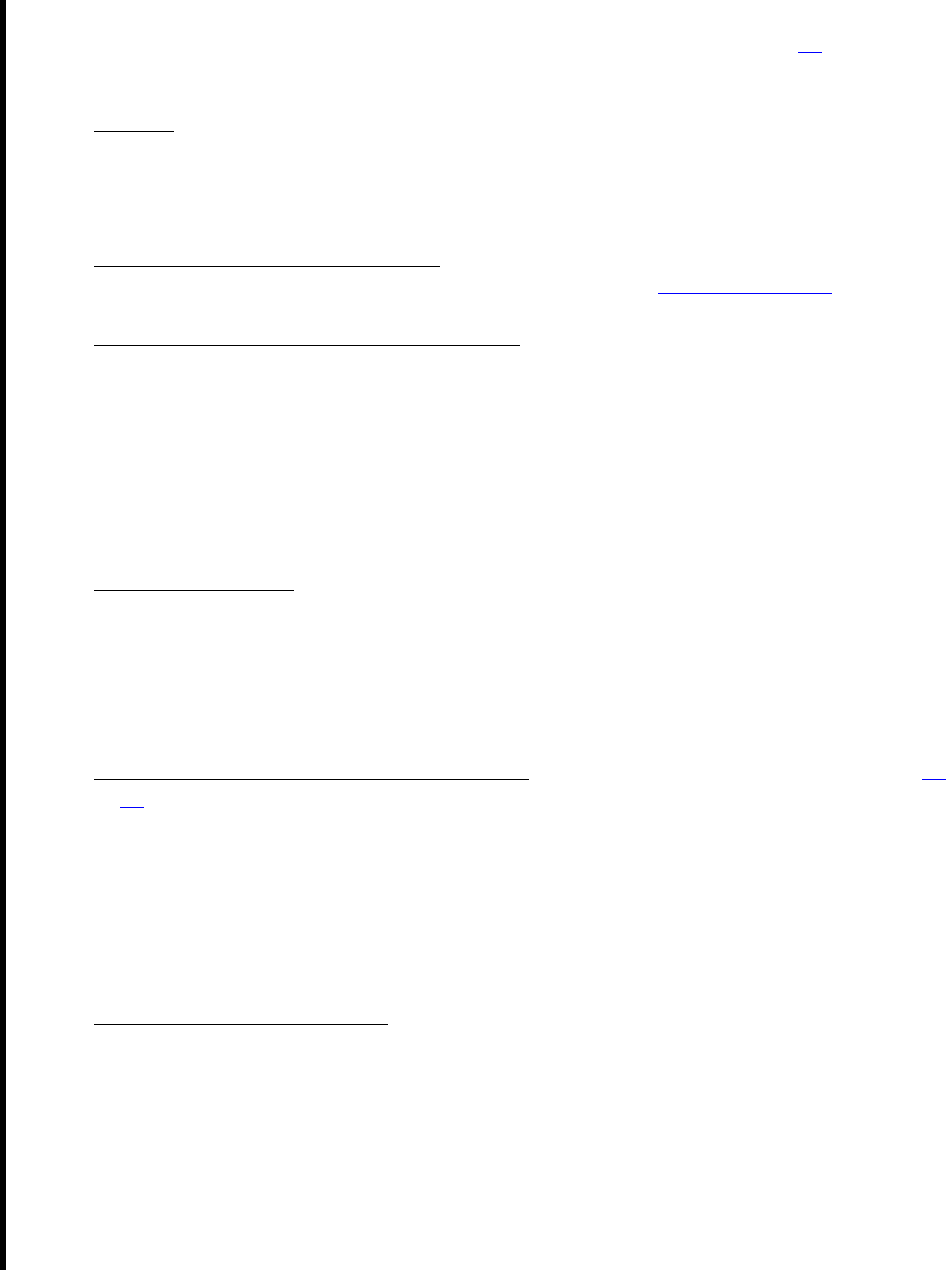

2.6 MMEL PL Global Change (GC) Designation. The FAA may designate an MMEL PL

as a GC for a variety of reasons, including the provision of immediate relief for items

required by a new regulatory requirement, policy change, or new technology. A GC

designation will not typically occur in great number or regularity, and their application

and use will typically be limited. The sole purpose of a GC designation is to allow

operators to obtain timely MEL relief for installed items referenced in an MMEL PL

prior to the release of a revised MMEL or applicable Design Change Approval Letter

(e.g., STC Relief Approval Letter). An operator is not required to include GC designation

relief in their MEL.

2.6.1 GC Designation Identification. MMEL PLs with a GC designation are identified by the

letters “GC” after the MMEL PL revision number on the title page. For example,

“MMEL PL-54, Revision 10 GC.” MMEL PLs with a GC designation will contain a

header box explaining their applicability (e.g., to what types of aircraft, operators, and/or

operations the GC applies). The header box will also contain requirements on how to

apply the sample proviso(s) of the GC to an operator’s MEL. See Figure 2-2.

Figure 2-2. Sample Global Change Header Box

MMEL GLOBAL CHANGE (GC)

This is an approved addendum to all existing MMEL documents. Operators may

seek use of the specific relief contained in this PL by revising their minimum

equipment list (MEL). In doing so, each applicable sample proviso stating the

relief in this PL must be copied verbatim in the operator’s MEL. Approval of a

revised MEL is gained utilizing established procedures through the assigned

Principal Operations Inspector (POI). This GC expires 9/13/2025.

2.6.2 GC Designation Applicability. An MMEL PL with a GC designation is typically

applicable to all aircraft. MMEL PLs will specify applicability (inclusion or exclusion)

when the GC designation is not applicable to all aircraft types. The Principal Operations

Inspector (POI) has the authority to approve the inclusion of an installed item in the

operator’s MEL on the basis that an MMEL PL with a current GC designation is an

approved addendum to the existing MMEL. The POI should contact the FOEB Chair

prior to approving the MEL if there is a concern about the applicability of the GC

designation for that specific aircraft.

2.6.3 GC Designation Expiration. The GC designation typically has an expiration date. The

expiration date may be extended by the FAA’s initiative or upon request by an FOEB

Chair. Keep in mind that even if the GC designation expires, the MMEL PL is still

DATE “DRAFT” AC 91-67A

2-5

effective. In other words, the FOEB can continue to use an effective MMEL PL for

MMEL development and revision, however, after the expiration of a GC designation,

MEL relief through the MMEL PL is no longer available.

2.6.4 GC Designation Validity. The MEL relief available in an MMEL PL with a GC

designation is valid until any of the following occur:

• The aircraft’s MMEL is revised to include information in the applicable MMEL PL;

• An applicable Design Change Approval Letter is issued; or

• The MMEL PL GC designation expires.

Note: When the relief available in an MMEL PL with a GC designation is no

longer valid, the operator must ensure their MEL is not less restrictive than the

relief provided in the current MMEL or applicable Design Change Approval

Letter.

DATE “DRAFT” AC 91-67A

3-1

CHAPTER 3. MINIMUM EQUIPMENT LIST (MEL)

3.1 General. An MEL allows an operator to continue to operate an aircraft with certain

inoperative items or to reposition the aircraft to a place where repairs can be made. The

MEL is intended to permit operations with inoperative items of equipment for the

minimum period of time necessary until repairs can be accomplished. It is important that

repairs be accomplished at the earliest opportunity in order to return the aircraft to its

design level of safety and reliability.

Note: Unless specified otherwise, the term “MEL,” used throughout this AC,

refers to both: (1) the MEL approval under LOA D095, consisting of an MMEL

and a procedures document, and (2) the MEL approval under LOA D195,

consisting of an operator-developed MEL. When required for clarity, this AC will

distinguish between an MEL approval under LOA D095 or D195 by using the

terms “procedures document,” or “operator-developed MEL,” respectively.

3.1.1 Requirement for All Aircraft Equipment to be Operative. Except as provided in

§§ 21.197 and 91.213(d), or under the provisions of an MEL and LOA, all instruments or

equipment items installed on an aircraft in compliance with the airworthiness standards or

operating rules must be operative for takeoff.

3.1.2 MEL Characteristics. An MEL and its associated LOA issued under the provisions of

§ 91.213(a) constitute an approved STC for the aircraft. An MEL allows an operator to

continue a flight (or series of flights) with certain items inoperative or to reposition to a

place where repairs can be made. An operator’s MEL may be more restrictive than the

MMEL, but it will not be less restrictive.

3.1.3 MEL Development and Content. MEL development is the responsibility of the operator.

Operators base their MEL on the MMEL applicable to the aircraft M/M/S, or the generic

single-engine airplane MMEL, as appropriate. When developing an MEL, the operator

should list all MMEL items for which the operator requests relief, based on their aircraft

configuration and operation. See Chapters 7 and 8 for detailed information concerning

MEL content. Except for NEF program items, MEL relief is only available for items

listed in:

1. The MMEL,

2. An applicable Design Change Approval Letter (e.g., STC Relief Approval Letter), or

3. An applicable MMEL PL with a current GC designation.

Note: See Chapter 10 for information on how to obtain relief for an item not

listed in items 1–3 above.

3.1.4 MEL Restrictions. An operator’s MEL will not be in any way less restrictive than the

following:

DATE “DRAFT” AC 91-67A

3-2

• The MMEL from which it was developed;

• Title 14 CFR operating rule;

• The operator’s LOA D095 or D195;

• The approved flight manual limitations and emergency procedures;

• Applicable MMEL PLs with current GC designation;

• STC/instructions for continued airworthiness (ICA) (as applicable); and

• Applicable ADs.

3.1.5 MEL Conflicts with ADs. Occasionally, an AD applies to an item that may be authorized

to be inoperative under the MEL. In those cases, the operator must fully comply with the

terms of the AD or an FAA-approved alternative method of compliance (AMOC) with

the AD. When provisions of an AD allow operation of the aircraft on the condition

certain installed items be used or be operative, those affected items must be operative,

even if the MEL provides for the deferral of repair.

3.1.6 MEL Management Program Not Required. An operator, as defined by this AC, is not

required to have an MEL management program. However, a means of recording

discrepancies and corrective actions must be available to the pilot in command (PIC)

when operating under the provisions of § 91.213(a).

3.2 Three Methods for Operating an Aircraft with Inoperative Equipment.

Section 91.213 provides three methods for operating an aircraft with inoperative

instruments or equipment installed. The relief could be obtained:

• Through an MEL and LOA;

• Under the provisions of § 91.213(d); or

• Under a special flight permit (SFP) issued in accordance with §§ 21.197 and 21.199.

3.2.1 Experimental Aircraft. An operator may not operate an aircraft for which the FAA issued

an original experimental Airworthiness Certificate with inoperative items unless

specifically authorized in the aircraft’s operating limitations.

3.3 MEL LOA. The FAA indicates approval of an MEL under the provisions of § 91.213(a)

through the issuance of an LOA authorizing the operation of the specific aircraft with

inoperative items in accordance with the MEL and the conditions and limitations of the

LOA. The MEL and the LOA together constitute an STC for the aircraft.

3.3.1 LOA D095 Versus LOA D195. For aircraft operated under parts 91, 133, and 137

(including part 91 operations conducted by parts 141 and 142 CHs), the FAA provides

two types of approvals for MELs under the provisions of § 91.213(a): LOA D095 and

D195.

DATE “DRAFT” AC 91-67A

3-3

3.3.1.1 MEL Approval Under LOA D095. The MEL approved under LOA D095

consists of the LOA, the aircraft M/M/S-specific MMEL, and the procedures

document. See Chapter 7 for detailed information regarding procedures

document content.

3.3.1.2 MEL Approval Under LOA D195. The MEL approved under LOA D195

consists of the LOA and the operator-developed MEL document, which is

based on the aircraft M/M/S-specific MMEL. See Chapter 8 for detailed

information on operator-developed MEL content.

3.3.2 Multiple Aircraft for a Single Operator. If an operator has multiple aircraft or more than

one type of aircraft, the aircraft serial number, registration number, and M/M/S will be

entered on the LOA for each aircraft. It is possible for an operator to have some aircraft

with an MEL approved under LOA D095 and other aircraft with an MEL approved under

LOA D195. Only one LOA D095 and one LOA D195 can be issued per operator.

3.3.3 Operational Control. LOAs are issued to the operator exercising operational control of

the aircraft. For example, under an aircraft dry lease agreement, the lessee assumes

operational control of the aircraft. Since the lessee is the operator of the aircraft, the

lessee may use only an MEL LOA specifically issued to them. The lessee cannot use an

MEL authorization issued to any other person (e.g., the lessor or another lessee).

3.3.4 Multiple Operators of a Single Aircraft. An MEL LOA is issued to a specific operator for

a specific aircraft. It is common for multiple operators to use a single aircraft on a

nonexclusive basis (e.g., multiple dry leases for the use of any one aircraft can be in place

at one time). In such instances, each individual operator is required to request an MEL

LOA in their own name. An operator may operate only under the MEL LOA issued to it.

Under timesharing, interchange, or joint ownership agreements, as defined in § 91.501(c),

the LOA is issued to the person exercising operational control.

3.4 Aircraft Operated Under Multiple 14 CFR Parts. Section 91.213(c) requires an

operator who has an approved MEL issued under either part 91K, 121, 125 (including

part 125 LODA holders), or 135 to use that MEL for part 91 operations. Only the

approved operator may use their MEL in part 91 operations. If a part 91K, 121, 125,

or 135 operator (the lessor) dry leases their aircraft to another operator (the lessee), the

lessee should obtain their own MEL since it cannot operate under the lessor’s MEL. MEL

authorizations are issued to the person exercising operational control.

3.5 Fleet MEL. An operator may develop a fleet MEL for multiple aircraft of the same

M/M/S. The operator is not required to list aircraft serial or registration numbers on a

fleet MEL. When a fleet MEL is used, aircraft of the same M/M/S may have differing

numbers of specific items installed. Operators may use a fleet MEL to reflect all of the

items applicable to a specific aircraft fleet type. This is allowable, provided the MMEL

applies to all of the M/M/S aircraft contained in the fleet. For example, the MMEL

applies to all Textron Aviation 500 Series Models: 500, 501, 550, S550, and 560 aircraft.

DATE “DRAFT” AC 91-67A

3-4

3.5.1 Identify Each Model and Configuration Difference. A fleet MEL will identify each

aircraft configuration difference, when appropriate. Operators may use whatever

methodology they deem appropriate to distinguish the applicability of individual MEL

items to aircraft within the fleet. Methods include, but are not limited to, registration

number, serial number, pre/post-Service Bulletin (SB) accomplishment, or system

characteristics (e.g., three-display configuration and five-display configuration). The

method chosen should make it clear to users which individual MEL item applies.

3.5.2 Modifications Within a Fleet. The aircraft manufacturer determines the configuration of

the aircraft, items installed, and official parts listed during the initial aircraft type

certification process conducted at the time of manufacture. Any subsequent installation or

removal of items is accomplished through the use of an STC or other

FAA-approved/accepted data (as appropriate). Operators with a fleet MEL may continue

to operate under the provisions of the current fleet MEL with new items installed in one

or more fleet aircraft. However, operators may not defer repair of the new items until the

items are included in the MMEL and the fleet MEL is revised to include the additional

items.

DATE “DRAFT” AC 91-67A

4-1

CHAPTER 4. CONDUCTING OPERATIONS WITHOUT AN MEL

4.1 Operating Without an MEL. This chapter provides guidance for operators who elect to

conduct flight operations under the provisions of § 91.213(d).

4.1.1 No Application Required. No application, written request, or approval is required to

operate under § 91.213(d).

4.1.2 Section 91.213(d). Operators who do not have an MEL per § 91.213(a) or (c) may takeoff

an aircraft with inoperative instruments or equipment items provided the conditions

detailed in § 91.213(d)(1)–(4) are met.

4.1.2.1 The following aircraft may be operated under § 91.213(d):

• Rotorcraft, non-turbine-powered airplane, glider, lighter-than-air aircraft,

powered parachute, or weight-shift-control aircraft, for which an MMEL

has not been developed.

• Small rotorcraft, non-turbine-powered small airplane, glider, or

lighter-than-air aircraft for which an MMEL has been developed.

4.1.2.2 Certain aircraft may not be operated under § 91.213(d), including:

• Turbine-powered airplanes.

• Large rotorcraft for which an MMEL has been developed.

• Large non-turbine-powered airplanes for which an MMEL has been

developed.

Note: An operator may not operate an aircraft for which the FAA

issued an original experimental Airworthiness Certificate with

inoperative items unless specifically authorized in the aircraft’s

operating limitations.

4.1.2.3 In addition to the above, § 91.213(d) requires:

• Instruments and equipment required by § 91.213(d)(2) must be operative;

• The maintenance action required by § 91.213(d)(3) has occurred; and

• A determination has been made in accordance with § 91.213(d)(4) that the

inoperative instrument or equipment does not constitute a hazard to the

aircraft.

4.2 Removal, Deactivation, and Placarding. When an operator elects to operate without an

MEL, any inoperative instrument or equipment items must either be repaired, removed,

deactivated, or inspected, and then placarded. Repair, removal, deactivation, or inspection

must be performed by a person authorized to perform aircraft maintenance in accordance

with § 43.3.

DATE “DRAFT” AC 91-67A

4-2

4.2.1 Removal. Removal of any item requires an appropriately authorized person under § 43.7

to:

• Properly record the removal of the item in maintenance records in accordance with

§ 43.9;

• Properly adjust the aircraft’s W&B information and equipment list, if required;

• Placard the cockpit controls or indicators, as appropriate;

• Complete and submit an FAA Form 337, Major Repair and Alteration (Airframe,

Powerplant, Propeller, or Appliance), as appropriate; and

• Approve the aircraft for return to service, as appropriate.

4.2.2 Deactivation. When an item is “deactivated” or “secured,” or both, the specified item

must be put into an acceptable condition for safe flight. Deactivation may involve more

than simply turning off a system switch, which does not remove power from the system.

Deactivation may involve pulling and securing the circuit breaker and/or removing the

equipment. Deactivation of an inoperative system is not preventive maintenance as

described in part 43 appendix A. Regardless of the method of deactivation, a person

authorized to approve the aircraft for return to service under § 43.7 must make the

maintenance record entry required by § 43.9. No person may operate the aircraft without

the entry required by § 43.9.

• Only appropriately qualified maintenance personnel may conduct procedures

requiring specialized knowledge or skill, or requiring the use of tools or test

equipment. The satisfactory accomplishment of all maintenance procedures,

regardless of who performs them, is the responsibility of the operator.

• An appropriately authorized person must accomplish the deactivation.

4.2.3 Placarding. Each inoperative item must be placarded (e.g., marked “inoperative”) to

inform and remind the flightcrew and maintenance personnel of the item’s condition. To

the extent practical, placards will be securely affixed to a location adjacent to the control

or indicator for the item affected. The placard is not required to be in a particular form,

but it will be legible and visible to the flightcrew. The placard may not obscure other

controls or indicators and should not interfere with aircraft operation. Unless otherwise

specified, placard wording and location will be determined by the aircraft operator.

4.3 Continued Operation with Inoperative Items. The operator of the aircraft must ensure

any inoperative instrument or item of equipment, permitted to be inoperative by

§ 91.213(d)(2), is repaired, replaced, removed, or inspected at the next required

inspection, and when listed discrepancies include inoperative instruments or equipment,

shall ensure that a placard has been installed, as required by § 43.11.

DATE “DRAFT” AC 91-67A

4-3

• The person performing the required inspection must give the aircraft owner or lessee

a signed and dated list of all discrepancies not repaired.

• The person performing the required inspection must ensure each inoperative item that

remains inoperative is placarded appropriately.

4.4 Safety Risk Analysis of Proposed Operation with Inoperative Equipment Items.

Before operating an aircraft with inoperative items permitted under § 91.213(d), the

operator should carefully evaluate whether the aircraft and crew are capable of safely

conducting the proposed operation under anticipated flight conditions with the

inoperative equipment. The safety risk analysis should include:

• A determination that the inoperative instrument or equipment, including failure

conditions, do not constitute a hazard to the operation;

• A determination that the inoperative instrument or equipment is not required for the

planned operation, such as oceanic/remote, or international operations;

• Interrelationship and effects of multiple instrument or equipment item failures;

• Adverse weather;

• Night operations;

• Departure and destination airports and their surrounding environment;

• En route environment;

• Diversion and alternate airport options;

• Additional crew workload caused by inoperative items; and

• Crew fatigue.

DATE “DRAFT” AC 91-67A

4-4

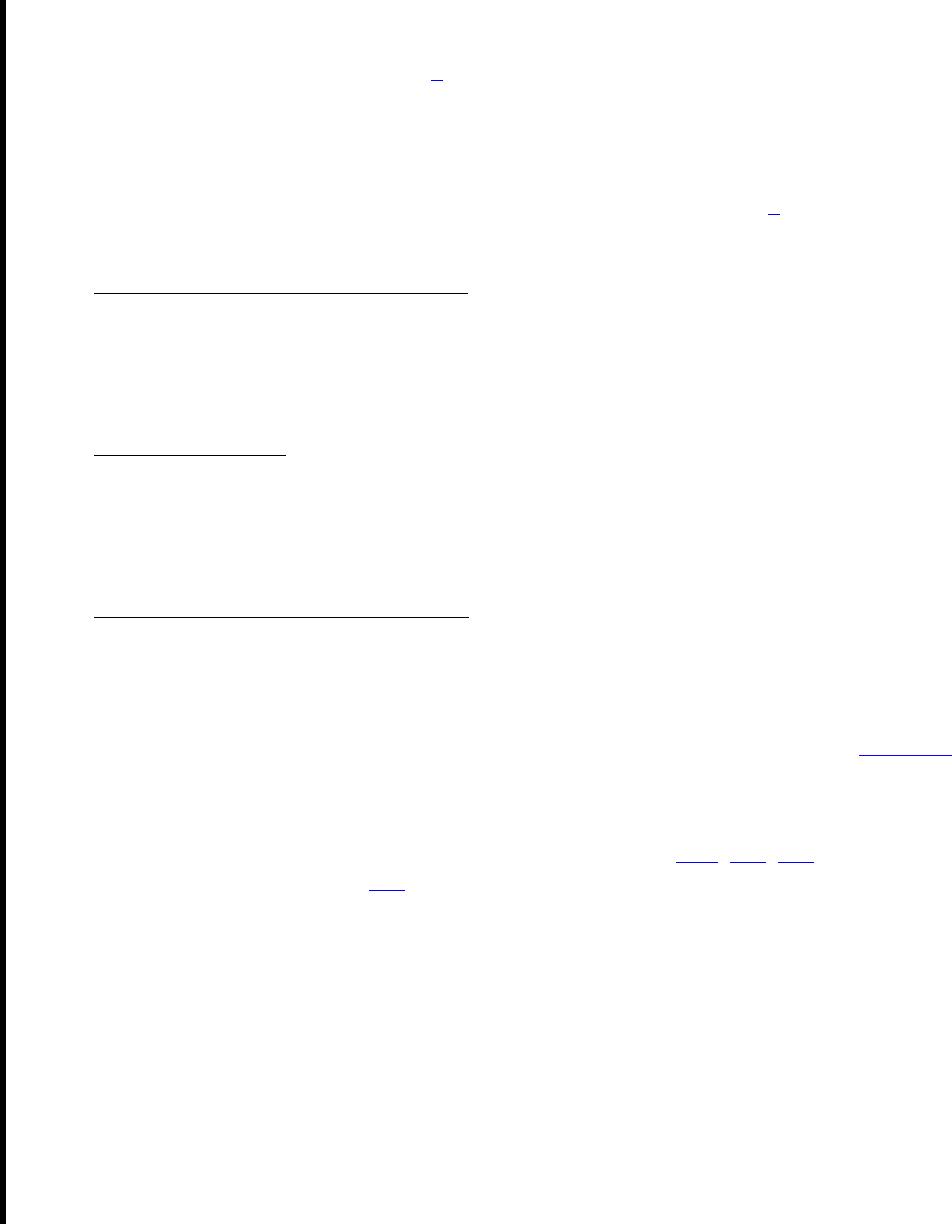

Figure 4-1. PIC Decision Sequence

Figure 4-1 illustrates the sequence of events involved in operating an aircraft under § 91.213(d)

with inoperative items.

DATE “DRAFT” AC 91-67A

5-1

CHAPTER 5. CONDUCTING OPERATIONS WITH AN MEL

5.1 Operating with an MEL. If the aircraft has an MEL and LOA, the PIC may defer

allowable inoperative items by following the MEL procedures. When operating under the

provisions of § 91.213(a), the MEL and LOA must be available to the PIC. The MEL

may be in hardcopy format (printed) or via another method approved by the

Administrator (e.g., electronically). Indirect methods of MEL and LOA access, such as

telephone, radio, or data link, are not acceptable.

5.1.1 Applicability. MEL item relief may be applied to an MEL item newly identified as

inoperative up until takeoff. Takeoff, for the purposes of this AC, is defined as the act of

beginning a flight in which an aircraft is accelerated from a state of rest to that of flight.

For the purposes of MEL relief, this means the point at which the pilot begins to apply

power to initiate the takeoff from the runway or takeoff surface.

5.1.2 Item Failures During or After Engine Start, During Taxi, or Any Time Prior to Takeoff.

The MEL does not allow a flight to continue if a discrepancy is discovered before

takeoff, but not yet not addressed by repair or deferral. An aircraft must not takeoff with

inoperative items until the MEL deferral process has been completed. For instance, if the

MEL procedures for a specific item require a mechanic’s inspection, takeoff would be

prohibited until the required inspection is complete.

5.1.3 Item Failures After Takeoff. MEL relief does not apply for item failures occurring after

takeoff. After takeoff, the flightcrew should handle item failures in accordance with the

Airplane Flight Manual (AFM)/Rotorcraft Flight Manual (RFM) approved procedures. A

record of the equipment failure must be made in the aircraft’s maintenance records.

Before the next takeoff, the inoperative item must either be repaired, or the PIC must

follow MEL deferral procedures. Therefore, any item failure that occurs after takeoff,

must be addressed before the subsequent takeoff.

5.1.4 Safety Risk Analysis of Proposed Operation with Inoperative Items. Before operating an

aircraft with inoperative items using an MEL, the operator should carefully evaluate

whether the aircraft and crew are capable of safely conducting the proposed operation

under anticipated flight conditions with the inoperative equipment. The safety risk

analysis should include, but is not limited to:

• A determination that the inoperative instrument or equipment, including the failure

condition, does not constitute a hazard to the operation;

• A determination that the inoperative instrument or equipment is not required for the

planned operation, such as oceanic, remote, or international operations;

• Interrelationship and effects of multiple instrument or equipment item failures;

• Adverse weather;

• Night operations;

• Departure and destination airports and their surrounding environment;

DATE “DRAFT” AC 91-67A

5-2

• En route environment;

• Diversion and alternate airport options;

• Additional crew workload caused by inoperative items; and

• Crew fatigue.

5.2 Documentation of Deferred Items. A means of recording discrepancies and corrective

actions must be in the aircraft and available to the PIC when operating under the

provisions of § 91.213(a). Additionally, when an instrument or equipment item is

discovered to be inoperative, an entry must be made in the aircraft maintenance records.

Since some operators do not carry aircraft logbooks in the aircraft, a discrepancy record

or log is an acceptable alternative. When an operator uses this type of discrepancy log in

lieu of the aircraft maintenance records, the operator must retain the log as a part of the

aircraft’s records, per § 91.417(b). If the operator elects to use the aircraft maintenance

record to log inoperative items, that portion of the record must be carried onboard the

aircraft during all operations.

5.3 Placarding. Each inoperative item must be placarded (e.g., marked as “inoperative”) to

inform and remind the flightcrew and maintenance personnel of the item’s condition. To

the extent practical, placards will be securely affixed to a location adjacent to the control

or indicator for the item affected. The placard is not required to be in a particular form,

but will be legible and visible to the flightcrew; may not obscure other controls or

indicators; and should not interfere with aircraft operation. Unless otherwise specified

(e.g., in an MEL proviso), placard wording and location will be determined by the aircraft

operator.

5.4 Performing (M) and (O) Procedures. The presence of either (M) or (O) symbols (as

explained below) in the “Remarks or Exceptions” column of the MEL indicate a specific

(M) or (O) procedure is required to be accomplished. In addition to carrying the

documents that comprise the MEL onboard the aircraft, the operator must have available

any applicable technical manuals needed to accomplish (M) and (O) procedures when

operating under the provisions of § 91.213(a).

5.4.1 (M) Procedures. The (M) symbol indicates a specific maintenance procedure that must be

accomplished prior to operation with the listed item inoperative. Normally, (M)

procedures are accomplished by qualified maintenance personnel; however, other

personnel may be qualified and authorized to perform certain functions. Procedures

requiring specialized knowledge or skill, or requiring the use of tools or test equipment,

should be accomplished by maintenance personnel. The satisfactory accomplishment of

all (M) procedures, regardless of who performs them, is the responsibility of the aircraft

operator. Appropriate procedures are required as a part of the aircraft operator’s MEL.

5.4.2 (O) Procedures. The (O) symbol indicates a specific operations procedure that must be

accomplished prior to operation with the listed item inoperative. Normally, these

procedures are accomplished by the flightcrew; however, other personnel may be

qualified and authorized to perform certain functions. These procedures may be required

for flight planning purposes, or they may require action by the flightcrew. Additionally,

DATE “DRAFT” AC 91-67A

5-3

MEL items affecting the aircraft W&B and cargo loading may require procedures for

additional personnel, such as those involved with aircraft load control. The satisfactory

accomplishment of all (O) procedures, regardless of who performs them, is the

responsibility of the aircraft operator. Appropriate procedures are required as a part of the

aircraft operator’s MEL.

5.5 Repair of Deferred Instruments or Equipment Items. The MEL is intended to permit

operations with inoperative items for the minimum period of time necessary until repairs

can be accomplished. It is important repairs be accomplished at the earliest opportunity in

order to return the aircraft to its design level of safety and reliability.

5.5.1 Accomplishing Repair, Replacement, Removal, or Inspection of Deferred Items. The

repair category intervals indicated by the letters A, B, C, and D in column 1 of the

MMEL are not applicable to an MEL approved under the provisions of § 91.213(a), but

operators must comply with any provisos defining a repair interval (e.g., flights, flight

legs, cycles, hours, days, etc.). The operator must have any inoperative items, which are

permitted to be inoperative, either repaired, replaced, removed, or inspected within the

proviso-defined repair interval period or at the next required aircraft inspection,

whichever comes first. If an operator chooses to defer maintenance on an inoperative

item beyond a required aircraft inspection, certificated maintenance personnel must

inspect the item for conformance with the requirements of the MEL and § 43.11(b).

• The person performing the required inspection must give the aircraft owner or lessee

a signed and dated list of all discrepancies not repaired.

• The person performing the required inspection must ensure each inoperative item that

remains inoperative is placarded appropriately.

DATE “DRAFT” AC 91-67A

5-4

Figure 5-1. PIC Decision Sequence

Figure 5-1 illustrates the sequence of events involved in using an MEL to operate an aircraft with

inoperative items. This chart is not required to be part of the operator’s MEL.

1

The PIC must ensure all applicable (M) and/or (O) procedures are performed and must

comply with applicable conditions or limitations listed in the “Remarks or Exceptions”

column of the MEL.

DATE “DRAFT” AC 91-67A

6-1

CHAPTER 6. APPLICATION FOR MEL LETTER OF AUTHORIZATION (LOA)

6.1 Application for an MEL Approval Issued Under LOA D095. An operator applying for

an MEL approval issued under LOA D095 must submit a signed, written request for

issuance of LOA D095 to the responsible Flight Standards office having jurisdiction over

the area in which the operator’s principal base of operations is located. An electronic

signature, or a signed and scanned request transmitted via email is acceptable. The

operator’s request must contain the information described in Figure 6-1, Sample

LOA D095 Request Letter. Except for reapplication after cancellation, rescission, or

revocation, the operator is not required to submit the procedures document to the FAA.

See Chapter 7 for detailed information on the procedures document content.

6.2 Application for an MEL Approval Issued Under LOA D195. An operator applying for

an MEL approval issued under LOA D195 must submit a signed, written request for

issuance of LOA D195, along with a copy of the operator-developed MEL (an electronic

copy is preferred), to the responsible Flight Standards office having jurisdiction over the

area in which the operator’s principal base of operations is located. An electronic

signature, or a signed and scanned request transmitted via email is acceptable. The

operator’s request must contain the information described in Figure 6-2, Sample

LOA D195 Request Letter for an Operator-Developed MEL That Conforms to the

Content Described in AC 91-67. Operators who conduct international operations and

currently hold an LOA D095 should state so in their request letter. See Chapter 8 for

detailed information on operator-developed MEL content.

6.3 Request for Approval of an MEL That Does Not Conform to This AC. An operator

may request approval of an operator-developed MEL that does not conform to the content

described in this AC. If an operator-developed MEL does not conform to the content

described in this AC, the operator should:

1. Submit a signed, written request to the responsible Flight Standards office for

approval of an MEL that does not conform to this AC (see Figure 6-3, Sample MEL

Approval Request Letter for an Operator-Developed MEL That Does Not Conform to

the Content Described in AC 91-67);

2. Explain in their request letter how their MEL meets the requirements of § 91.213(a);

3. Provide a copy of the operator-developed MEL (an electronic copy is preferred) with

the request; and

4. Be advised that approval of the MEL may be delayed.

6.4 Oversight. The FAA may request to review a procedures document or

operator-developed MEL during normal surveillance activity. If the FAA determines the

MEL does not comply with the conditions and limitations of the operator’s MEL LOA,

the FAA may rescind the LOA.

DATE “DRAFT” AC 91-67A

6-2

Figure 6-1. Sample LOA D095 Request Letter

To: Responsible Flight Standards Office

I request issuance of a Letter of Authorization (LOA) D095 under the provisions of Title 14 of

the Code of Federal Regulations (14 CFR) part 91, § 91.213 to [complete legal name of operator]

for the aircraft listed below.

I attest that I have a copy of the [state the make, model, series (M/M/S) Master Minimum

Equipment List (MMEL), revision number (e.g., Gulfstream Aerospace GVII-G500/G600

MMEL, revision 3)] and have developed a procedures document for the listed aircraft. The

procedures document conforms to the content described in Advisory Circular (AC) 91-67, and

contains:

1. The name(s) of the operator(s), aircraft serial and registration numbers (or “Fleet”),

aircraft M/M/S, and the MMEL revision number on which the minimum equipment list

(MEL) is based;

2. Maintenance (M) and Operations (O) procedures that correspond with the (M) and (O)

provisos listed in the MMEL;

3. A list of applicable MMEL items that contain the statement “as required by 14 CFR”;

4. Definitions, per current MMEL Policy Letter (PL)-25; and

5. A preamble, per current MMEL PL-36.

Principal base of operations address of the operator: